Pick

This Module is used for performing outbound picking operations at the workstation. It enables warehouse staff to scan outbound documents, receive picking tasks, and process order picking via automated equipment.

Workflow Overview

1. Accessing the Workstation

-

Warehouse staff navigates to the Pick Oubound page of the workstation.

-

Scan the outbound order to begin.

-

WCS will call the WMS interface to query the order records.

-

If no matching data is found, the workstation will display No Order Found.

-

If the order exists, the system will display relevant order information, such as SKU, Item Name, and Quantity. If multiple orders belong to the same group number, they will be picked together at the same workstation.

2. Start Picking Operation

-

Staff clicks Start Operation on the workstation UI.

-

WCS sends an Outbound Request to WMS.

-

WMS processes the request and performs the inventory commitment.

-

If commitment fails, WCS will display Inventory Commitment Exception on station page.

-

If successful, WMS will generate a Pick Action and send it to WCS.

3. Task Generation

-

WCS receives the pick action, then generates Job and Task.

-

The workstation displays a task list, and WCS uses orchestration rules to generate control commands.

4. Device Execution (Via RCS)

-

RCS dispatches the equipment to fetch the storage tote after receiving the commands.

-

When the tote leaves its storage location, RCS reports the event to WCS and WES.

-

When the tote arrives at the workstation, RCS sends a Task Completed to WES and WCS.

-

WES updates inventory to reflect that the stock is now at the workstation.

5. Manual Picking at the Station

-

Staff scans the tote barcode at the workstation, or using the BCR scanning.

-

WCS queries the Pick Action for that tote and displays the pick details (such as SKU, descriptions or quantity).

-

Staff scans each item's barcode to confirm picking and submits it.

-

Pick progress is reported to WCS and WMS.

-

Meanwhile, WCS determines whether the tote's pick task is completed:

-

If not completed, continue picking remaining items.

-

If completed, WCS sends a Putaway Request to WES.

- WES generates the Putaway action. Initiates the putaway inbound process, continuing with storage operations.

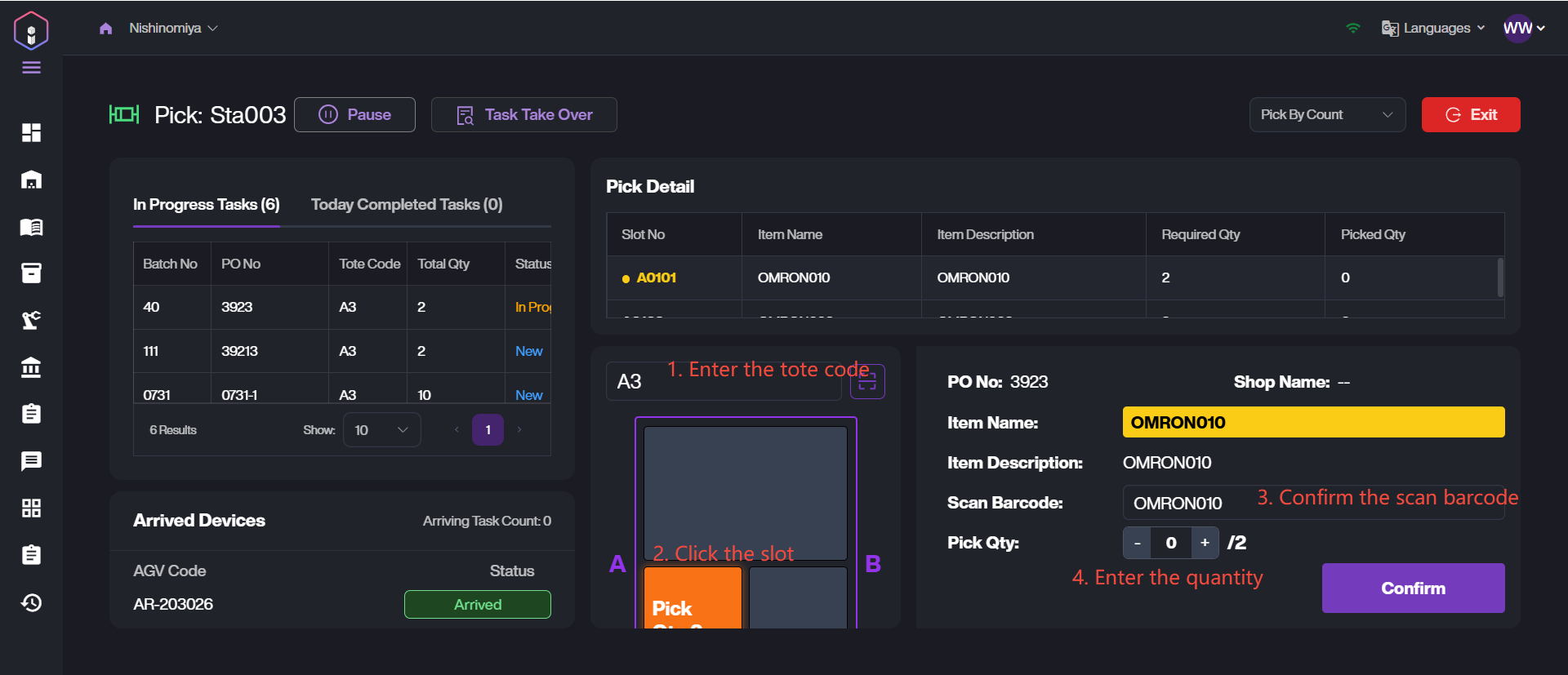

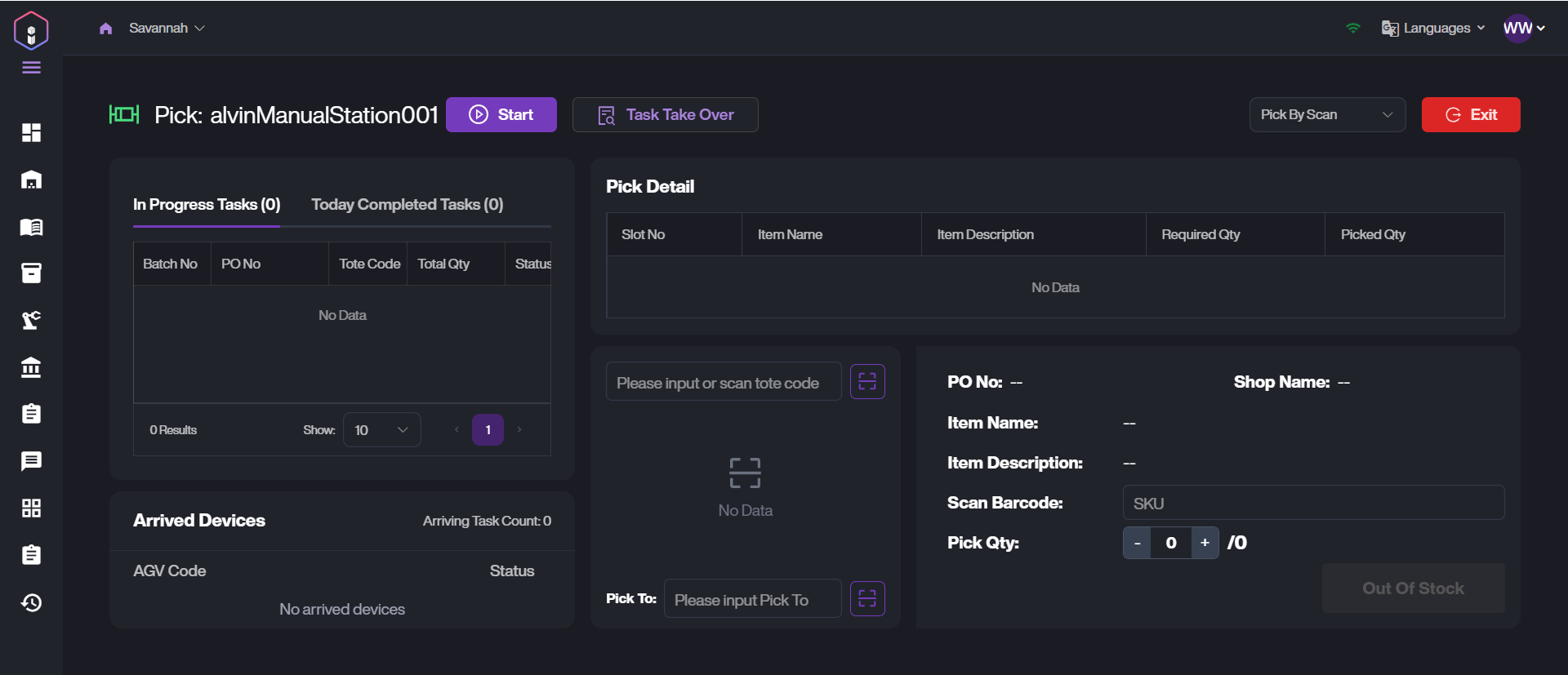

Web Operation

-

Go to Manual Station > Pick to Start.

-

Enter the Tote Code to proceed.

-

The pick detail will be displayed, which is bound to the tote code you enter.

-

Confirm the correctness of the task, including item name, required quantity and more.

-

Click the corresponding slot, scan or enter the scan barcode.

-

Type in Pick QTY.

-

Click Confirm to complete the pick task.

-

If the pick task contains multiple slots, please repeat executing Step 5 , Step 6 and Step 7.