Case Inbound

The Case Inbound process is designed to handle the automated putaway of totes that contain received goods from WMS. When goods are received in the WMS system and placed into totes, the WCS must support their automated delivery to storage locations via warehouse robots or other devices. This function is integrated across multiple systems: WCS, WES, RCS, and WMS.

This mode is typically activated through the Inbound Workstation, and offers efficient, semi-automated inbound flow with system-verified item data.

Workflow Description

The typical workflow for Case Inbound is as follows:

1. Empty Tote Request Generation

Upon start the Case Inbound process at the workstation, WCS generates empty tote request tasks based on the number of queue slots configured at the site.

2. Empty Tote Dispatching

-

These empty tote tasks are handed over to RCS, which dispatches vehicles to the station.

-

As vehicles arrive, their tasks are marked as complete in WCS and vehicle information is displayed on the screen.

-

Meanwhile, tote scanning feature is enabled.

3. Tote Placement and Scanning

-

Warehouse staff place the case onto the carrier and scan the tote barcode either manually or through a BCR device.

-

Once the barcode is scanned, WCS and WES check the receiving details.

-

Next, WES checks is there is an existing putaway task for the receipt. Meanwhile, transfer the receipt data to WMS.

4. Receiving Detail Validation

-

If no put away task exists, the error message is shown on WCS workstation - "No Receipt Found".

-

If any put away task exists, WCS displays the item detail and waits for operator confirmation.

5. Inbound Request Submission

-

If you confirm the item details on WCS, it will submit an inbound request to WES.

-

If there is anything incorrect, it requires the operator to manually confirm, then submit the inbound request to WES.

-

WES performs auto-receiving and location allocation.

-

If no location is available, WCS displays the error message "No Available Location".

-

If location is found, WES generates a putaway action and sends it back to WCS.

6. Put Away Execution

-

WCS generates the job and task execution strategy.

-

RCS delivers the movement command.

-

Once the tote reaches the storage location, the task is marked as complete across RCS, WCS, WES, and data is written back to WMS.

Additional Logic & Explanations

1. Empty Tote Request Count Logic

-

The number of ongoing tote requests must always match the configured queue size at the station.

-

As one vehicle arrives and completes a task, WCS will immediately generate a new tote request to maintain the buffer count.

2. Manufacturer-Based Dispatch Mode

If the map configuration is set to manufacturer dispatch mode, commands are delivered via a protocol template to equipment.

3. BCR Scanning Behavior

-

The system supports both manual and automatic scanning.

-

When using a fixed BCR scanner, the scanned barcode is:

-

Report the scanned tote number to the system.

-

Auto-filled into the input field upon the system receives the information.

-

Auto-submitted with automatic "Enter" action to trigger tote registration.

-

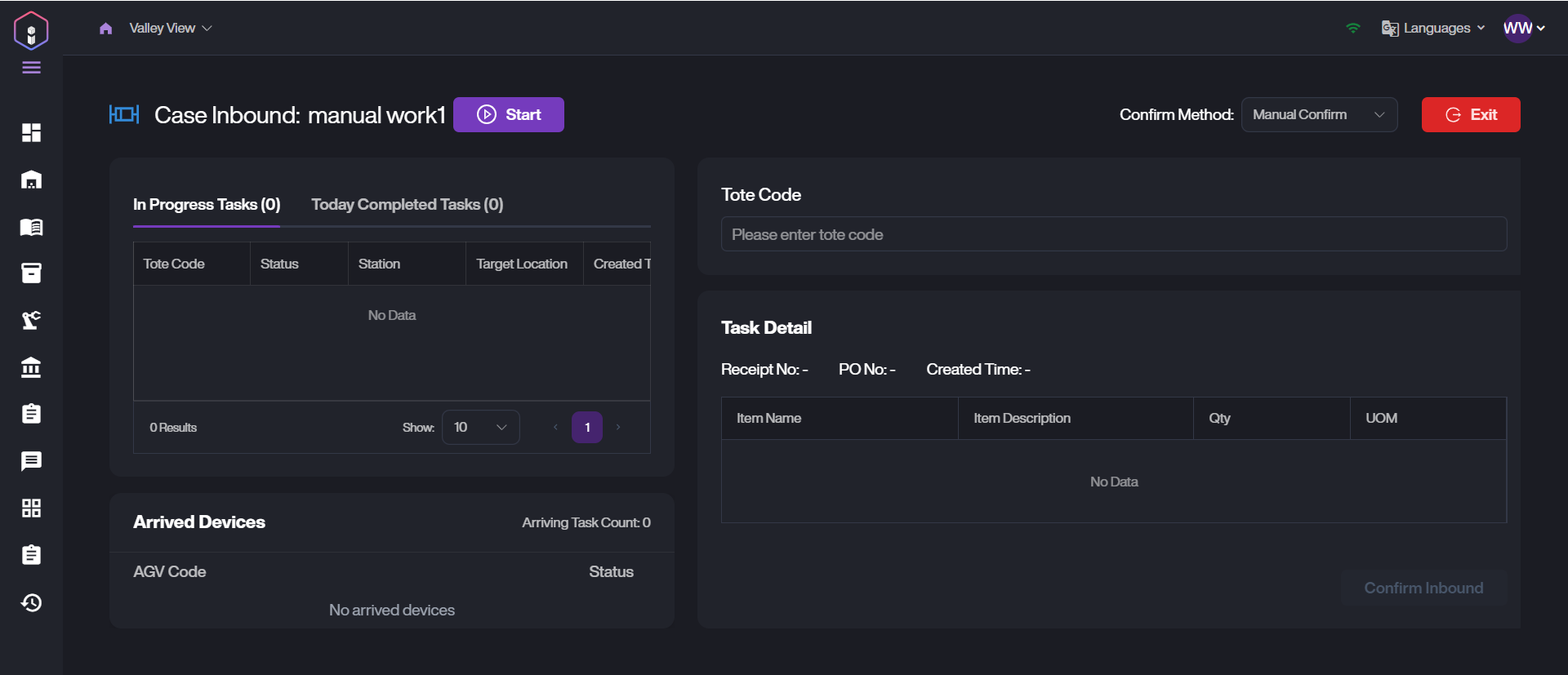

Workstation Page Features

The Empty Tote Inbound workstation page is divided into two sections for efficient operational visibility:

Left Panel

Arrived Device List: Dispalys the list of devices that are secheduled to arrive at the station.

PutAway Task List: Shows the generated putaway task list related to this workstation.

Right Panel

Tote Barcode Input Field: For manual scanning or auto-fill via BCR scanning.

Item Details: Displays item information.

Task Info: Shows related job ID, tote ID and assigned storage location if available.

Operation Tips: Step-by-step system guidance or error/warning messages based on current status or input.

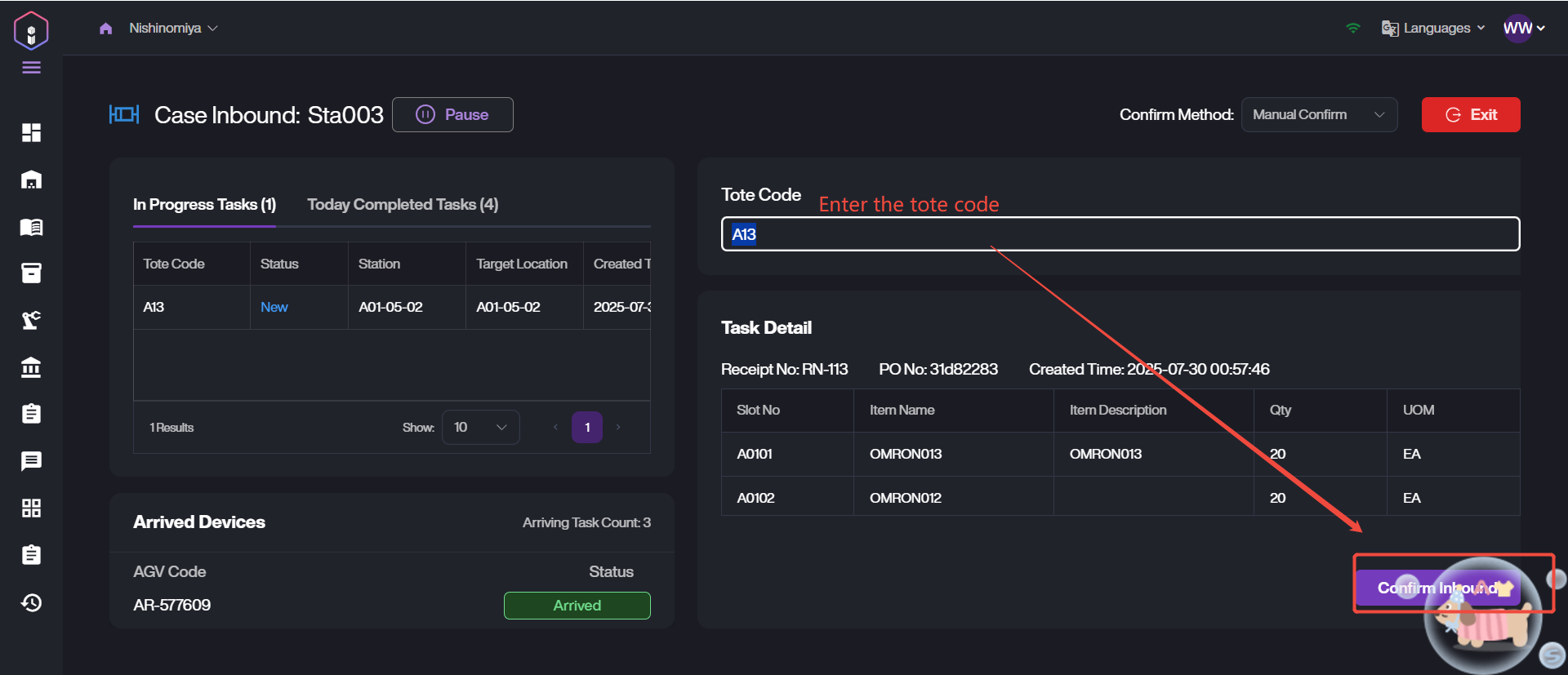

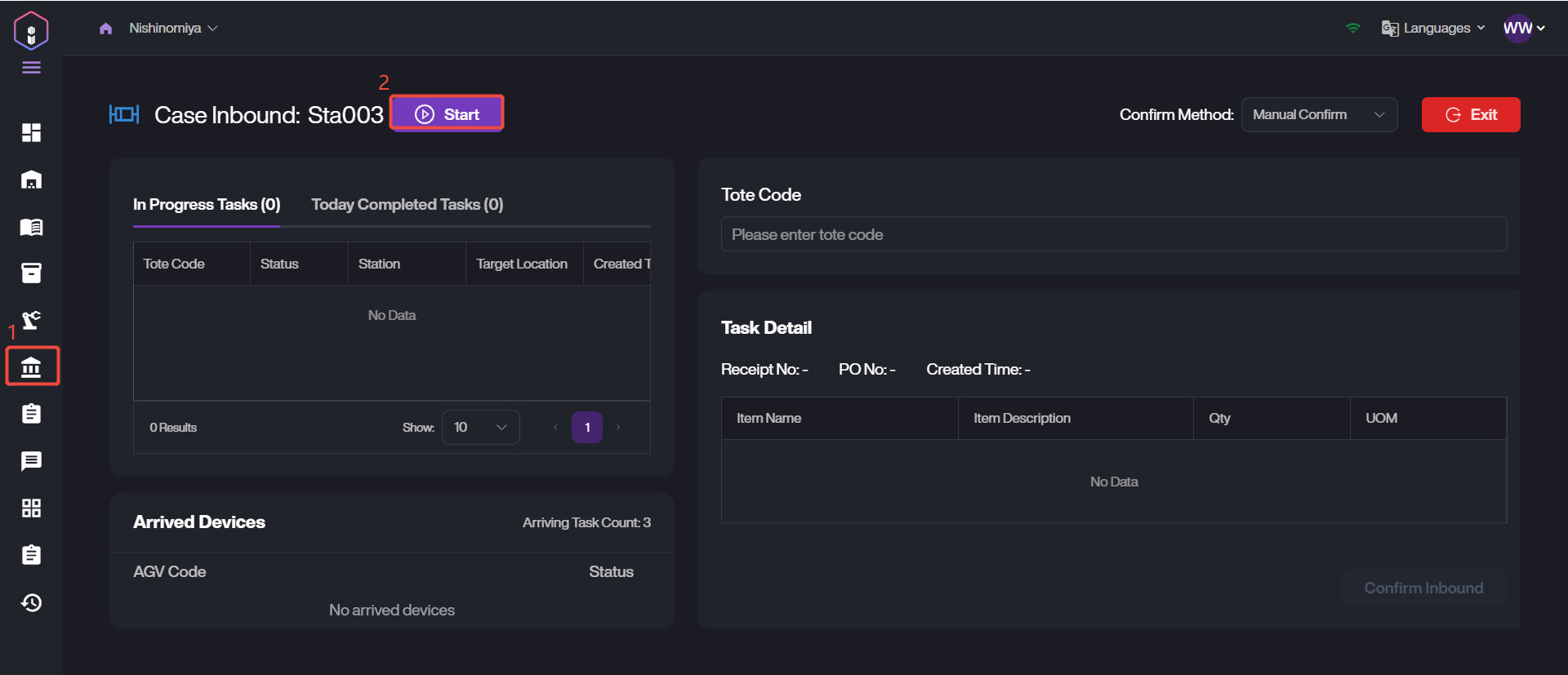

Web Operations

-

Navigate to Manual Station > Case Inbound.

-

Start the process.

-

Enter the tote code to retrieve the relevant data.

-

Confirm the correctness of the task detail, including receipt number, purchase order number, item name and quantity.

-

Confirm Inbound if all information is accurate.