Container Management

Overview

Containers are essential units used throughout warehouse storage and operations. They serve as the fundamental medium for handling, sorting, and storing goods. In automated warehouse environments, containers play an even more critical role, functioning as the base element for interaction with automation equipment such as conveyors, robots, and picking stations.

To accommodate different operational models and container types, WCS provides a dedicated Container Management module to manage and maintain all types of containers and their specifications.

Container Specification Management

Even of containers of the same type, there may be variations in size and structure — such as differences in length, width, height, number of layers, or compartments. To ensure accurate matching during storage allocation and equipment operation, the WCS system supports centralized container specification management.

Search & View

It allows users to quickly locate the container specification via the following Container Type (Bag, Tote, Tote Rack, Tote Cart, Pallet) and Spec Code.

The search result will be displayed in the container spec list, with the accessable action buttons.

Add New Container Spec

-

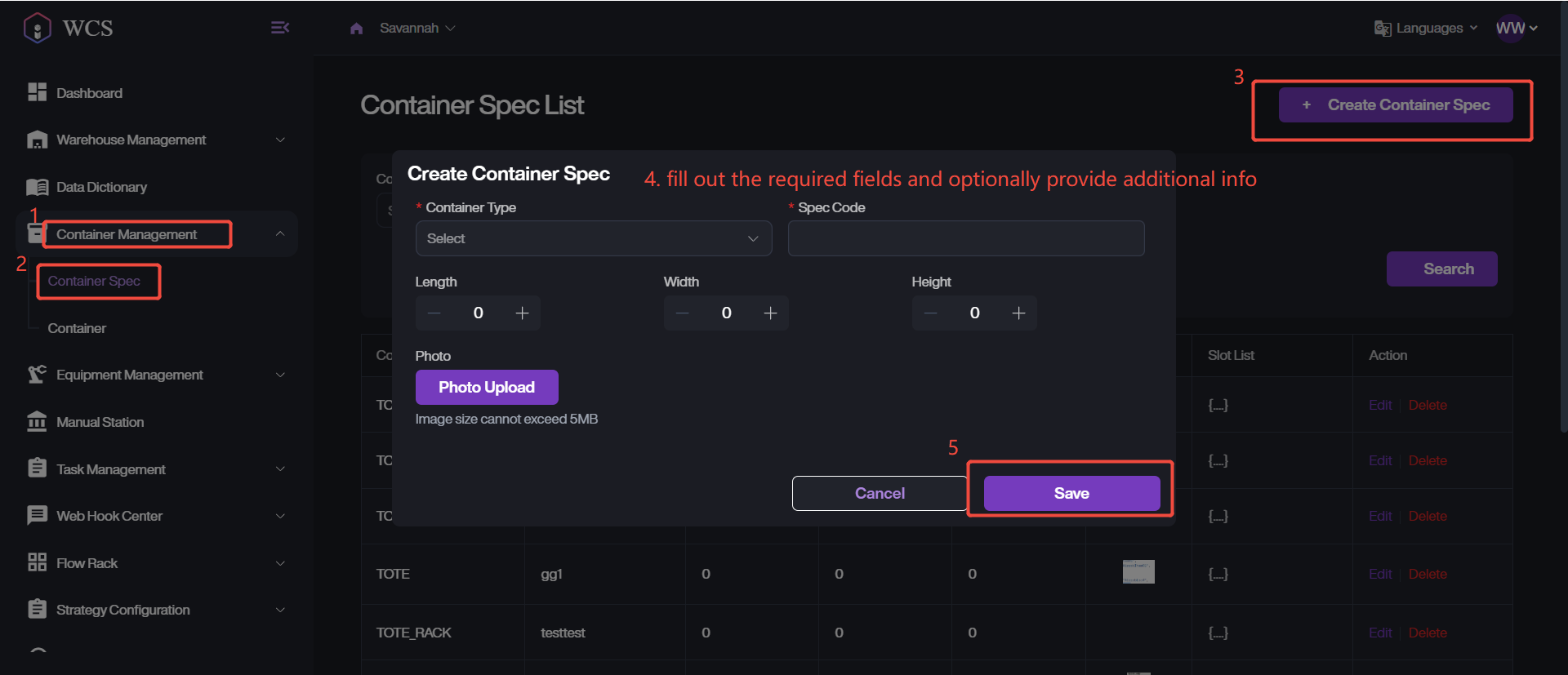

Navigate to Container Management > Container Spec > + Create Container Spec.

-

Choose the desired Container Type and enter the Spec Code.

-

Optionally fill out the dimensions (length, width and height) and upload the photo.

-

Click Save to complete the creation.

Edit/Delete Existing Container Spec

-

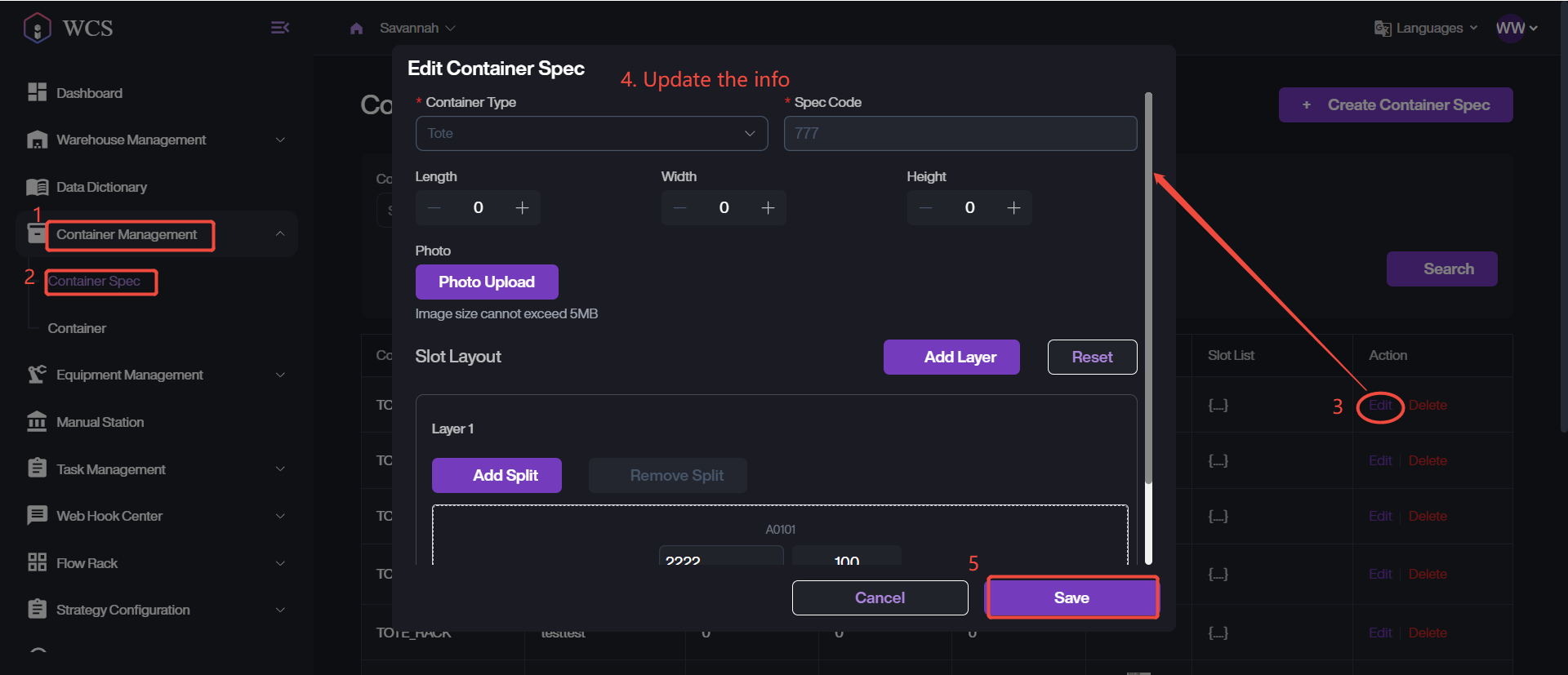

Locate the target container spec in the Container Spec List.

-

If you want to remove obsolete specifications, please directly click on Delete to complete the deletion confirmation.

-

If you want to update existing container specification details, please click Edit to continue.

-

Modify the necessary info.

-

Save the changes.

Container Management

This section is used to manage all container instances in the warehouse. Each container instance is tracked with attributes such as its code, type, specification, and current position. Containers may participate in various operational workflows such as inbound, outbound, picking, and movement.

Search & View

These filters are available to quickly retrieve the container entries: Container Code, Type, and Spec.

The search result will be displyed in the Container List, with the accessable action buttons.

Add New Container

There are two methods to add new containers: Single Create and Batch Create. Please choose the better one based on your needs.

Single Create

Add a single container manually.

-

Navigate to Container Management > Container > + Create Container.

-

Choose Single Create method.

-

Choose the desired Spec and enter the container code.

-

Click Save to complete the creation.

Batch Create

Create multiple containers in one action.

-

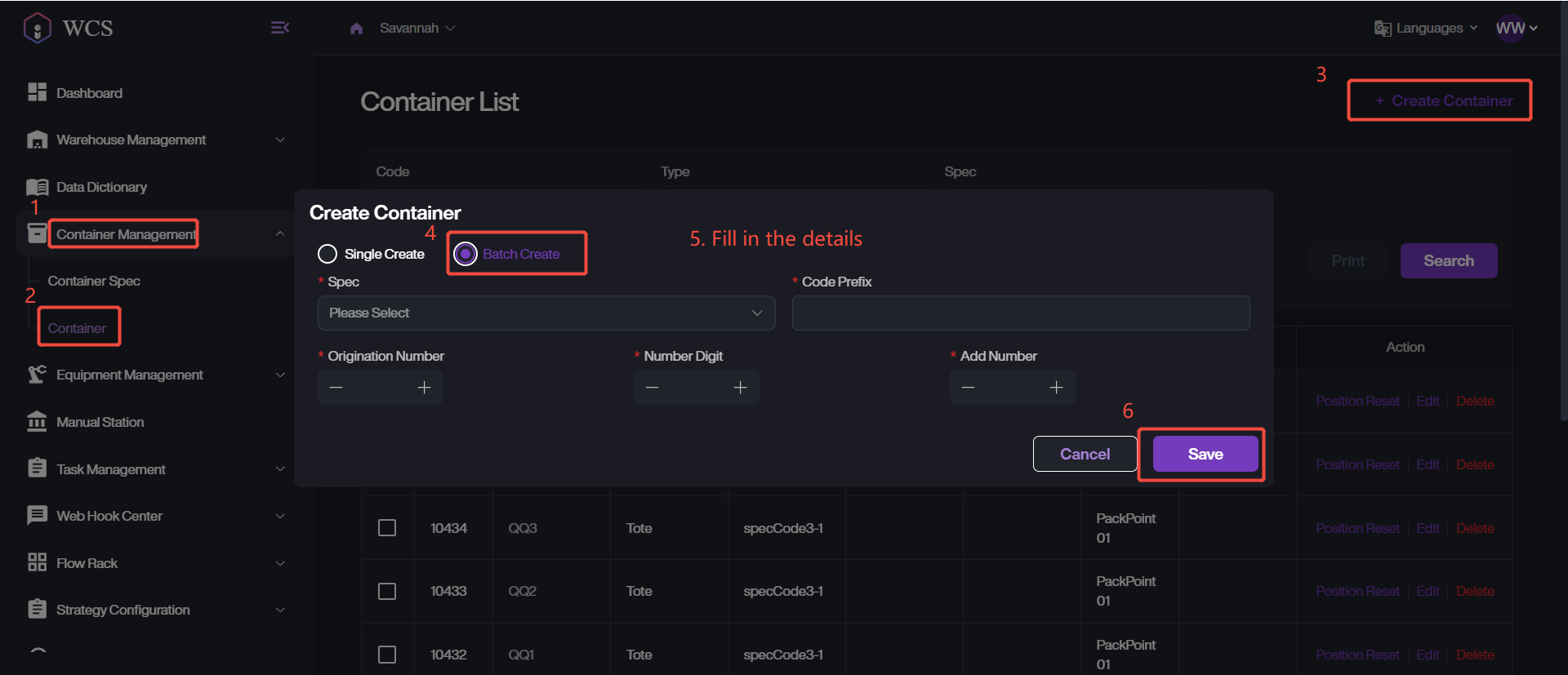

Navigate to Container Management > Container > + Create Container.

-

Choose Batch Create.

-

Fill out the required fields, including spec, code prefix , origination number, number digit, and add number.

For Example, the code prefix is ABC, Origination Number is 25, Number Digital is 6, Add Number is 5. The system will generate the following 5 container codes:

ABC000025, ABC000026, ABC000027, ABC00028, ABC000029.

| Field | Description |

|---|---|

| Code Prefix | The character prefix for the container code (letters only). |

| Origination Number | The starting number for code generation (numeric). |

| Number Digit | Total number of digits for the numeric portion (e.g., 6 will pad with leading zeros). |

| Add Number | The number of container codes to generate (numeric). |

- Click Save to complete the process.

Eidt/Delete Existing Container

-

Locate the target contaier in Container List.

-

Click on Delete to remove the container entry from the list.

-

Click on Edit to modify the Spec or Disable.

-

Save these changes.

Position Reset

Reset a container’s position under various scenarios (e.g., physical movement, exception handling).

Supported reset types include:

-

Reset to Empty: Clear container position when manually removed or when exiting the warehouse. Prevents it from occupying virtual slots.

-

Reset to Location: Reset container to a specific storage location.

-

Reset to Station: Reset container to a specific station (e.g., picking, packing).

-

Reset to Equipment: Reset container to a specific equipment unit (e.g., conveyor, robot).

Print Container Label

It allows users to print the container labels on this interface, please ensure you have installed and run the Local Connet App on you computer, avoiding disruptions during printing.

-

Select the target containers.

-

Click Print button to proceed.

-

Check the container correctness before printing, then select a local printer.

-

Enter print copies.

-

Click Print to execute this printing task.