Inventory Check

The Inventory Check module is used when warehouse staff need to verify the actual inventory of SKUs inside a tote (container). This function enables operators to request tote delivery to the manual station and inspect item information upon arrival.

Workflow Overview

-

The warehouse staff enters the Inventory Check workstation and clicks the Inventory Query button. The staff then inputs the search criteria to filter the data (e.g., SKU, batch number, location, box number).

-

After selecting the desired items, the staff clicks Confirm Outbound. The WCS submits an Inventory Check request to the WES.

-

WES creates an action and sends it back to the WCS.

-

The WCS receives the action and generates the job. Following the task prioritization strategy, the WCS also creates the task, which will be displayed on the workstation.

-

WCS sends the commands to RCS for equipment scheduling. When the box is moved from the storage location, a notification is sent to WES. Once the box reaches the workstation, WES is notified of the box’s arrival.

-

The warehouse staff scans the box barcode when it arrives at the station.

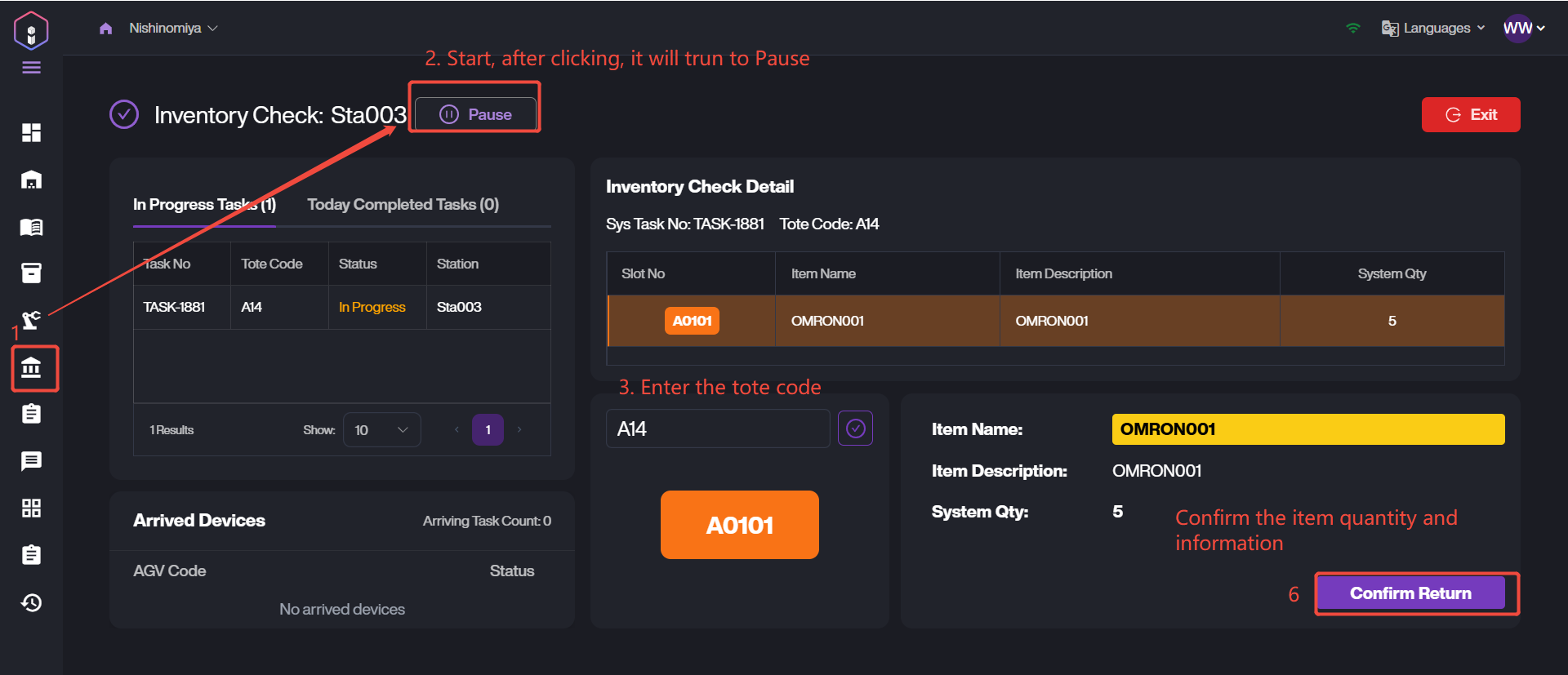

Web Operation

-

Navigate to Manual Station > Inventory Check.

-

Click on Start to begin the inventory check task.

-

Enter the tote code to retrieve the inventory check task, which is connected with this tote.

-

Confirm the correctness of the inventory.

-

Confirm Return to complete this task.