Build Pallet with Sorting By SKU

This topic introduces the transload workflow for an organization/customer whose "Transload Receive Mode" has been set as Build Pallet with sorting by SKU. In this mode, upon arrival at the warehouses, the products are sorted by SKU and stacked onto respective pallets according to their destinations. These pallets are scanned during loading and then shipped.

Add/Import Receipt

The inbound receipt can be created by importing from edited templates or EDI.

Inbound Receiving

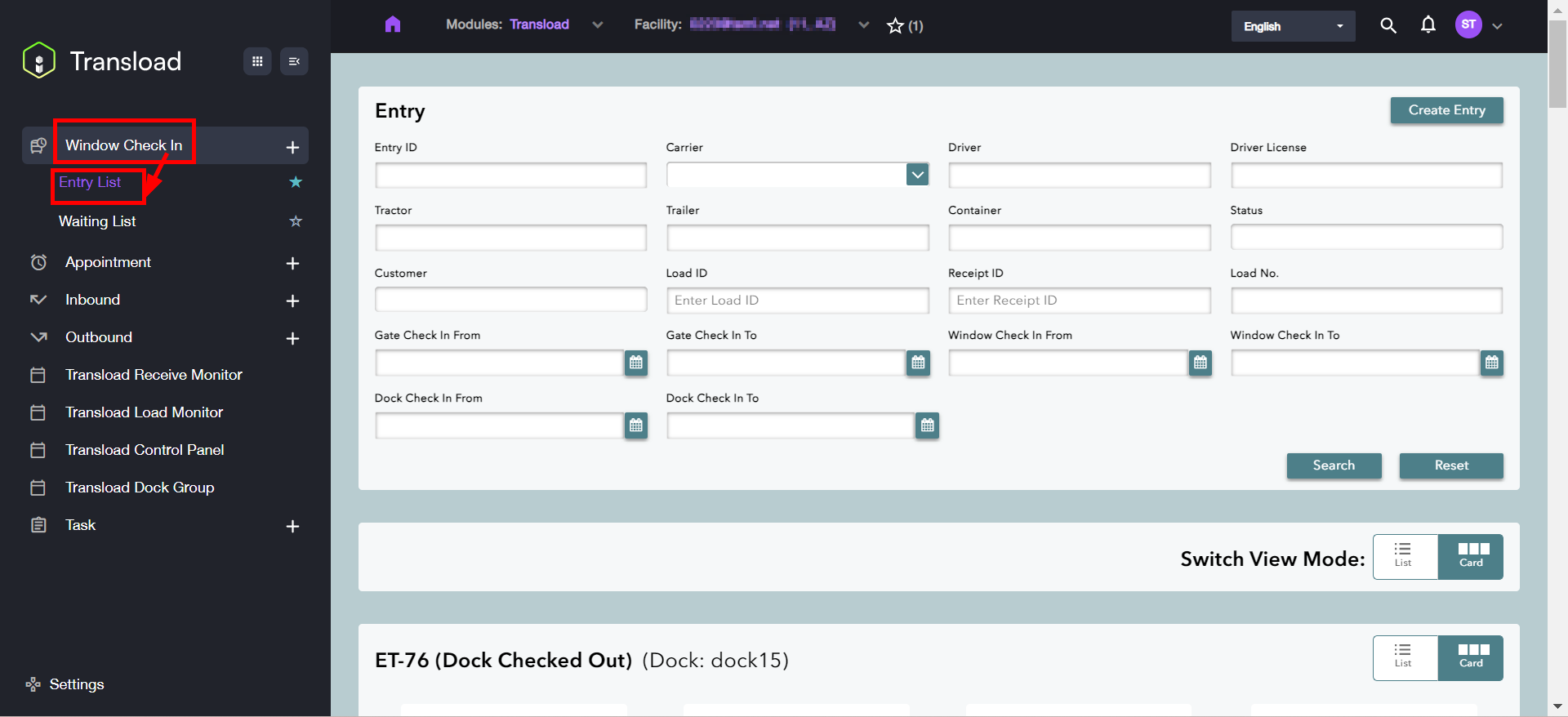

Upon the arrival of the products at the warehouse, finish window check-in and then transload receiving task.

- Log into Item Transload. In Window Check In > Entry List, create an entry and finish window check-in. A transload receive task is created and a specific assignee is appointed for this task.

-

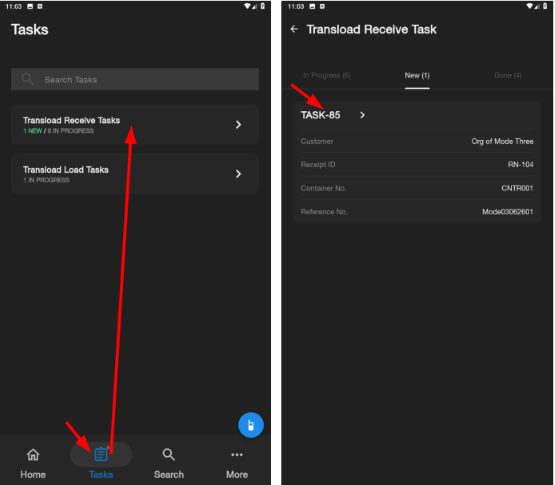

The assignee then finds and finishes the transload receive task in the Transload app on the work phone. Refer to the following instructions.

a. Log into the Transload app on the work phone.

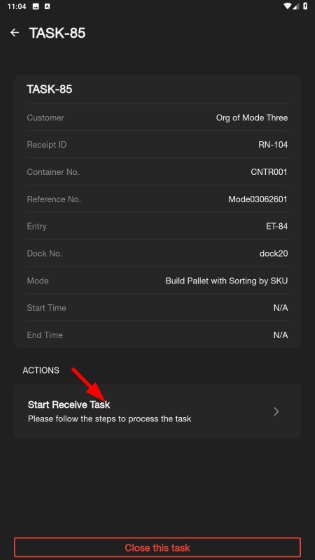

b. Go to Tasks > Transload Receive Tasks, find the desired task in the New tab, and tap the task ID.

c. Tap Start Receive Task.

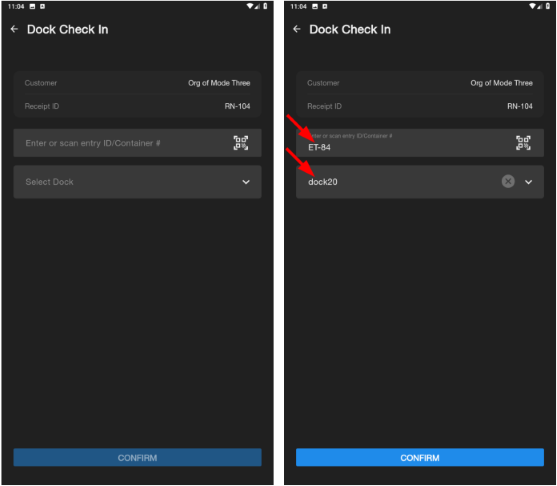

d. Enter or scan the Entry ID or Container No., select the dock No., and tap CONFIRM.

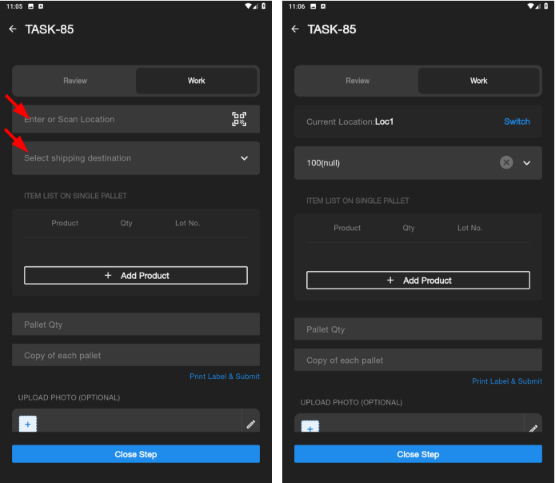

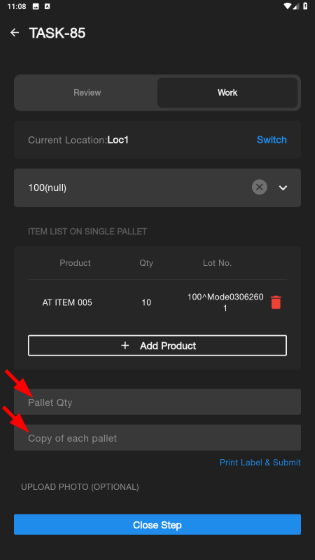

e. In the Work tab, scan or enter the location, and then select a destination. Then tap +Add Product.

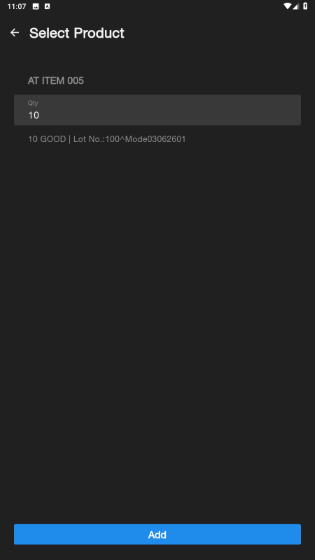

f. Enter into the text box the quantity of the products bound for the selected destination, and then tap Add in the bottom.

g. To configure pallets, enter the pallet quantity (the total quantity of pallets for the products) and the number of copies of pallet labels. Then tap Print Labels & Submit to print the pallet labels. For instance, there are 10 pieces of Product A expected to be received and they are placed onto two pallets. Each of the pallets stages 5 pieces and 4 labels for each pallet should be printed. In this case, enter 2 in "Pallet Qty" and 4 in "Copy of each pallet", so that in total 8 labels will be printed.

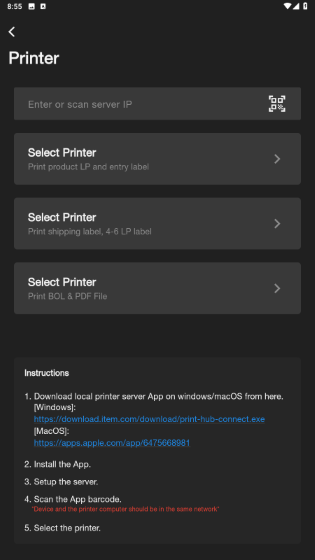

Be noted that if no printer has been set up, when you tap Print Label & Submit, the instruction for printer setup and printing procedure is described in the lower part of the page. You can also navigate to the Home page of the Transload App and go to Settings > Printer for printer setup.

h. Repeat the previous steps until all products for all destinations are placed onto all needed pallets and the labels are printed.

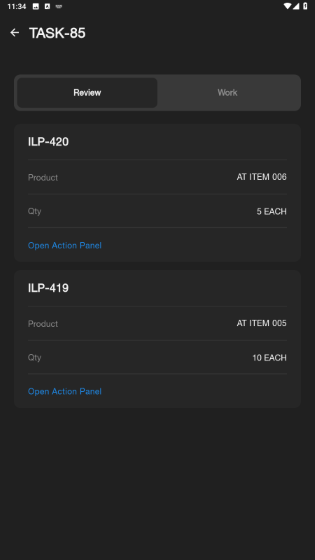

i. (Optional) You can tap the Review tab to view the records.

j. Tap Close Step.

k. Tap Close this task.

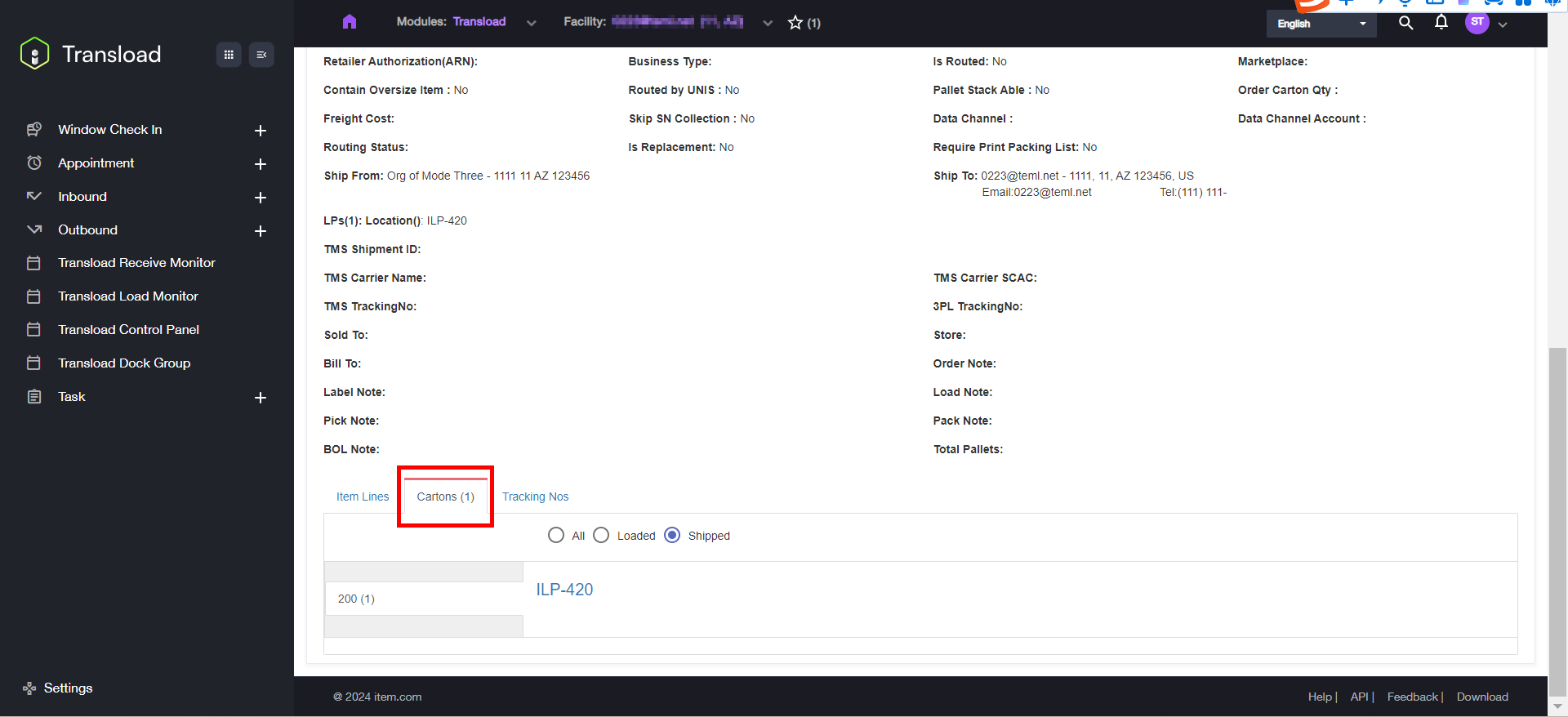

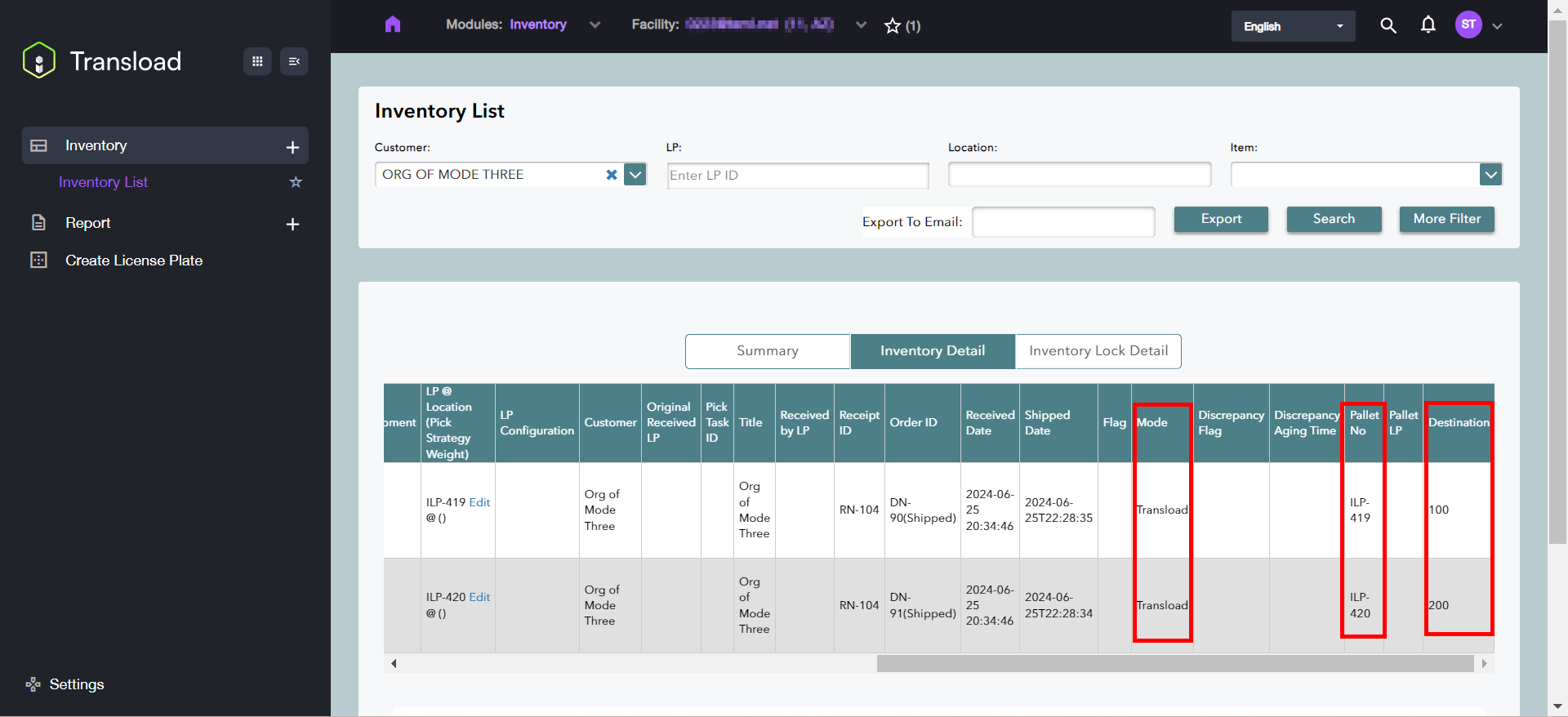

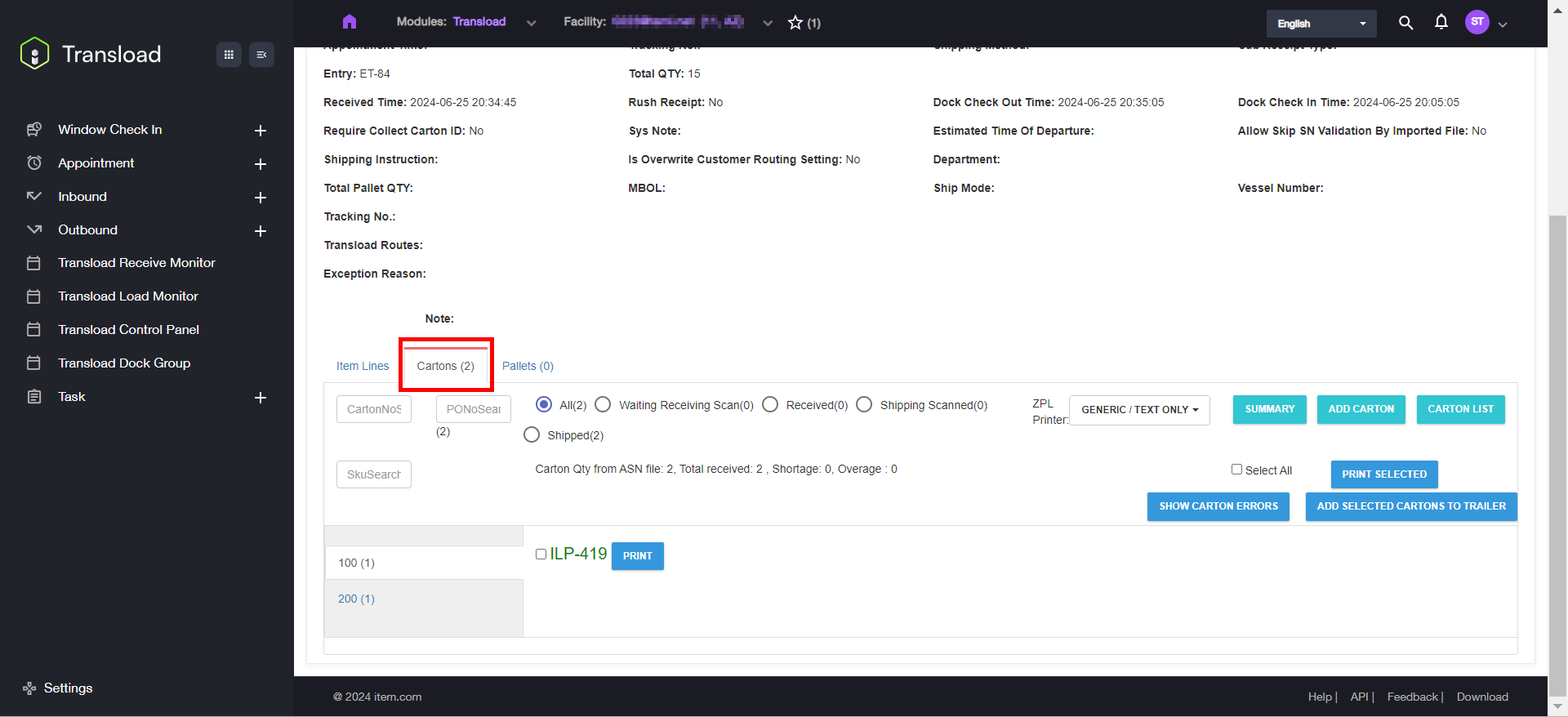

The transload receive task is finished. The inventories of the products are updated accordingly, such as the quantity, the pallet number, etc. The receipt is also updated, including the cartons' information.

Outbound Loading

-

In Item Transload, navigate to Outbound > Load. If the receipt is created manually, you need to click Add Transload Load and create a load with the required destination; if the receipt is created via EDI, then a corresponding Load/Order is already automatically created and you can just select this Load.

-

Go to Window Check In > Entry List, create an entry, and finish window check-in with the Load ID from last step. A transload load task is created and a specific assignee is appointed for this task.

-

The assignee then finds and finishes the transload load task in the Transload app on the work phone. Refer to the following instructions.

a. Log into the Transload app on the work phone.

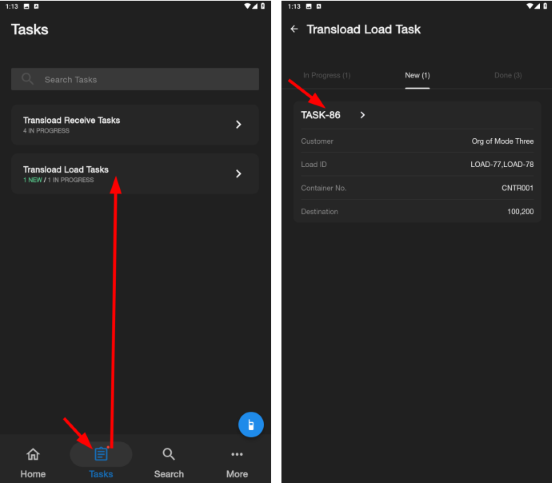

b. Go to Tasks > Transload Load Tasks, find the desired task, and tap the task ID.

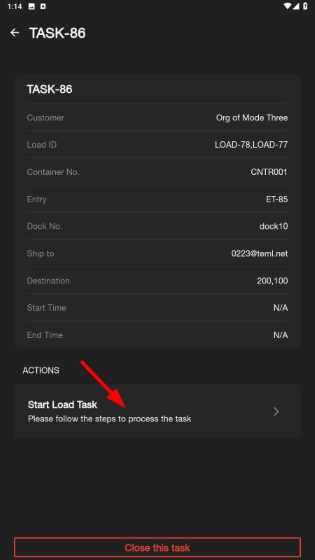

c. Tap Start Load Task.

d. Enter or scan the Entry ID or Container No., select the dock No., and tap CONFIRM.

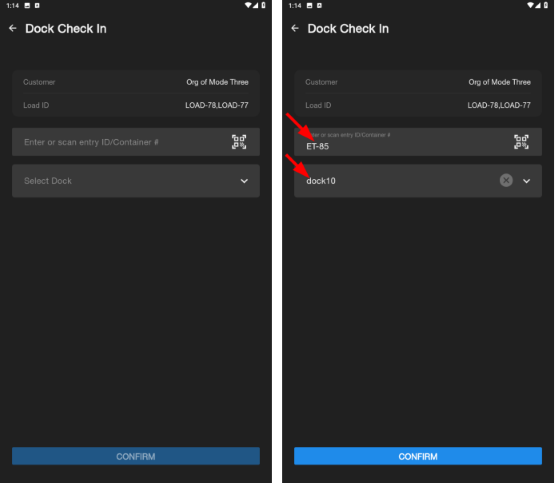

e. Tap a Load ID. In the Work tab, scan or enter the location, and then scan or enter the cartons or pallets that were received. The Load Qty is updated.

f. (Optional) If there is any damaged cartons or products found, tap the + icon to take photos of them. To unload any loaded cartons, tap Unload, select the cartons, and unload them.

g. Tap Complete Load when all the cartons are scanned.

h. Return to the previous page and tap Close this task when all the loads are completed.

The transload load task is finished and the status of both the Load and the Order will be marked as Shipped. The inventories of the products are updated accordingly, such as the quantity, the pallet number, etc.