Count

The Count process ensures inventory accuracy by confirming physical item quantities against the system records. This section guides warehouse personnel in completing inventory counting operations at the manual station through the WCS interface.

Workflow Overview

1. Enter the Count Station Page

-

The warehouse staff logs in to WCS and navigates to the Manual Station > Count page.

-

Click the Create Count button.

-

WCS automatically opens the WES count creation interface to initialize the counting process.

2. WES Create Count Task

-

WES generates the count task and sends corresponding count actions to WCS.

-

WCS receives the count actions, creates the internal jobs and tasks, and displays the task list on the manual station interface.

3. Task Dispatch & Bin Movement

-

WCS uses its orchestration strategy to generate movement commands and sends them to RCS.

-

RCS dispatches the robotic equipment to move the bins.

-

Once the bin leaves its storage location, RCS reports the event to both WCS and WES.

-

When the bin arrives at the manual station, RCS reports task completion.

-

At this point, WES updates the inventory status to At Station.

4. Station Physical Count

-

The operator scans the barcode (via manual or BCR).

-

WCS receives the bin submission, queries the corresponding count action, and displays the detailed count list on the interface.

-

The operator scans item barcode one by one beginning to count.

-

The operator confirms the counted quantities and verifies any discrepancies.

5. Submit Count Result

-

Once counting is finished, WCS submits the results to WES.

-

WES logs the inventory count outcome.

-

WCS determines whether the count for this bin is complete:

-

If incomplete, the system allows continued scanning and adjustment.

-

If complete, WCS sends a putaway request.

-

WES, then generates a putaway task, and the bin enters the inbound putaway workflow.

-

Appendix: Task Execution Strategy Logic for Count

In some cases, when a task is generated without a predefined destination station, the WCS must dynamically determine the appropriate station through task execution logic. Below outlines the decision-making mechanism:

Station Selection Logic

When the system needs to assign a station for a counting task, it evaluates available stations based on the following conditions:

-

The station's current active capability

activeCapabilitymatches the task's JobAction. -

The station's runningStatus is set to Running.

-

The number of in-progress tasks targeting this station is less than its traffic capacity.

Task Sorting Strategy

Tasks are sorted before assignment using two main criteria:

-

Priority: Higher-priority tasks are sorted first.

-

Creation Time: Older tasks take precedence if priorities are equal.

Station-Task Allocation Logic

Once eligible stations and tasks are identified and sorted, the system distributes tasks using a balanced allocation strategy:

1. Initial Balance Assignment

The system first attempts to balance the number of tasks assigned to each station based on their capacity.

For example, if:

-

Station A can accept 4 tasks

-

Station B can accept 2 tasks

Then, 2 tasks will first be assigned to Station A to balance the available capacity with B.

2. Round-Robin Allocation

After the initial balance is achieved, remaining tasks are distributed in a round-robin fashion among the eligible stations.

Final Assignment & Update

Once a station is selected:

-

The task's destination is updated to the selected station code.

-

The task's toMapCode is updated to reflect the station’s map code.

Task Overload Protection

-

Station cannot be overloaded: A station must not exceed its trafficCap, meaning the number of active tasks targeting that station must be less than or equal to the traffic capacity.

-

This ensures fair load distribution and avoids performance bottlenecks.

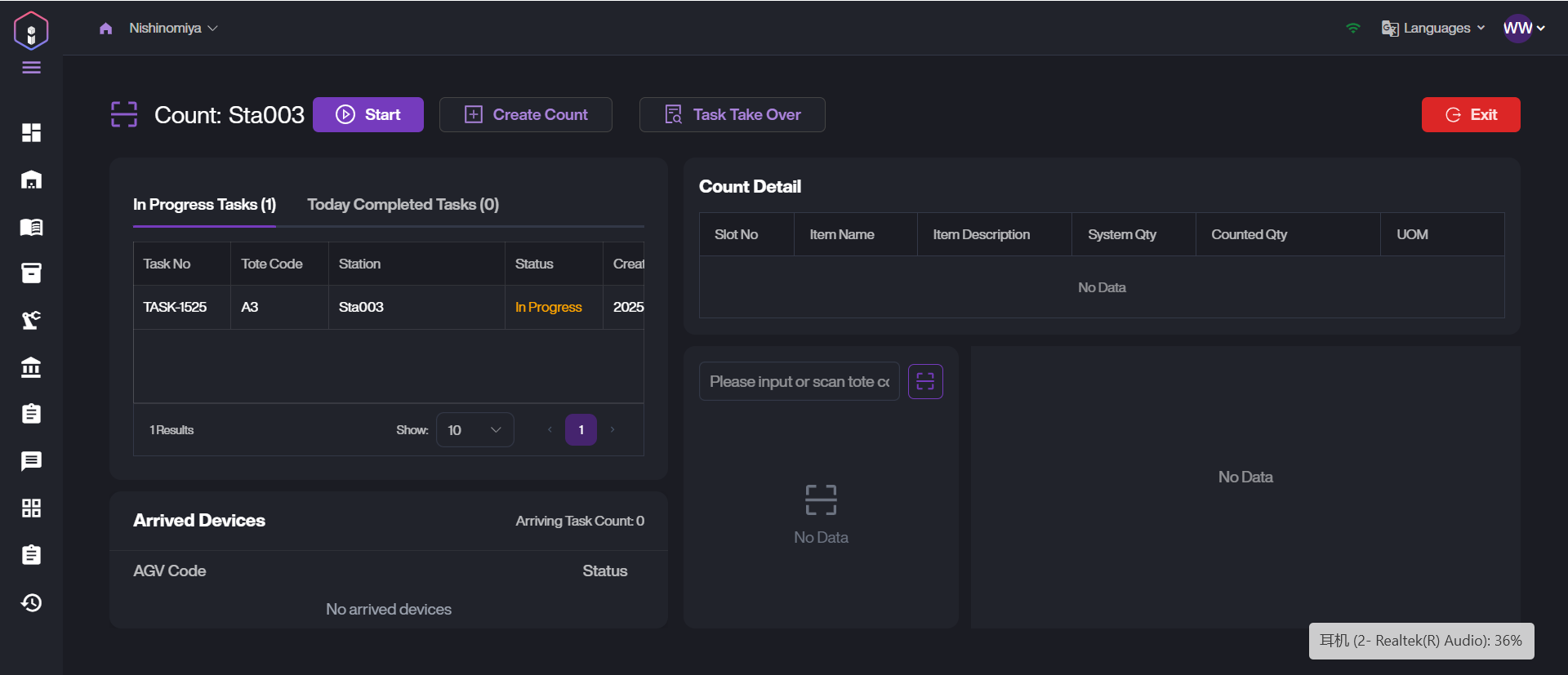

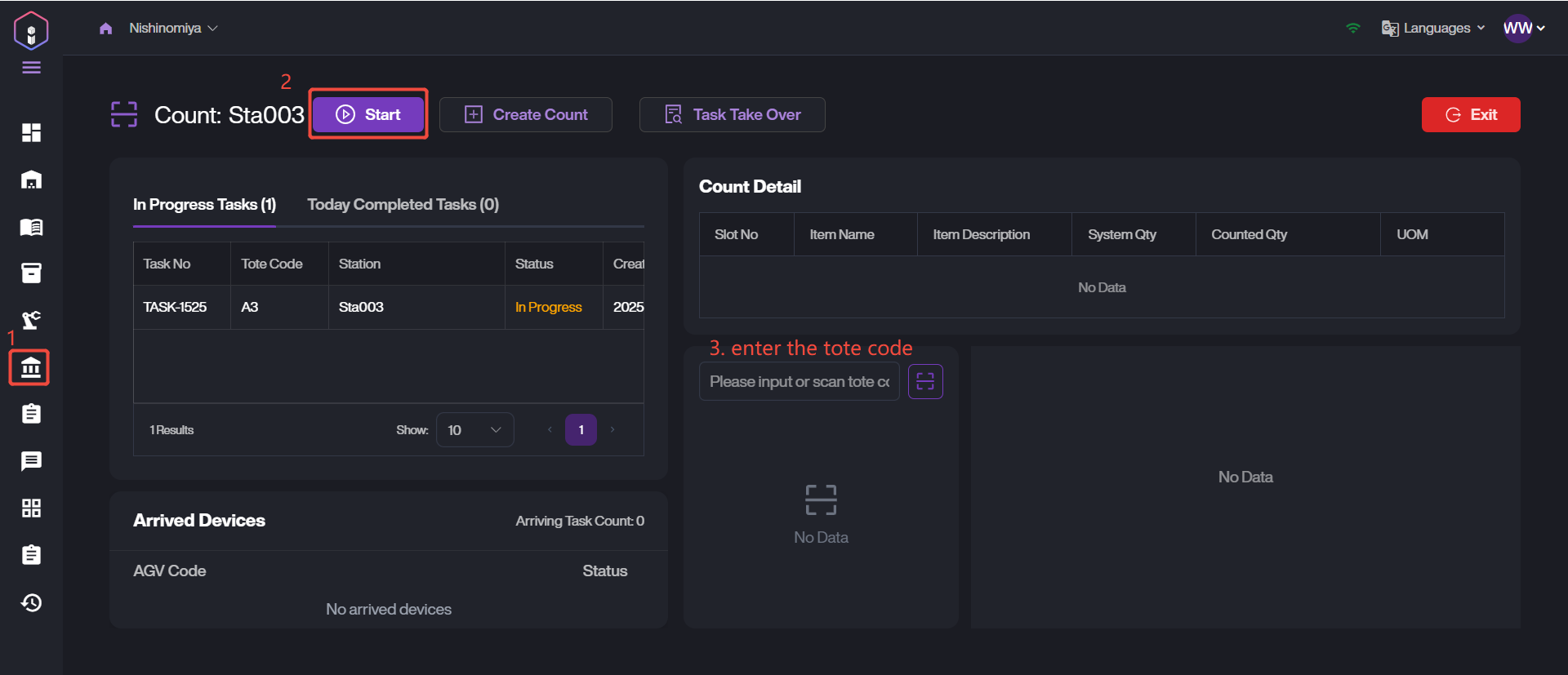

Web Operation

-

Go to Manual Station > Count to Start the counting process.

-

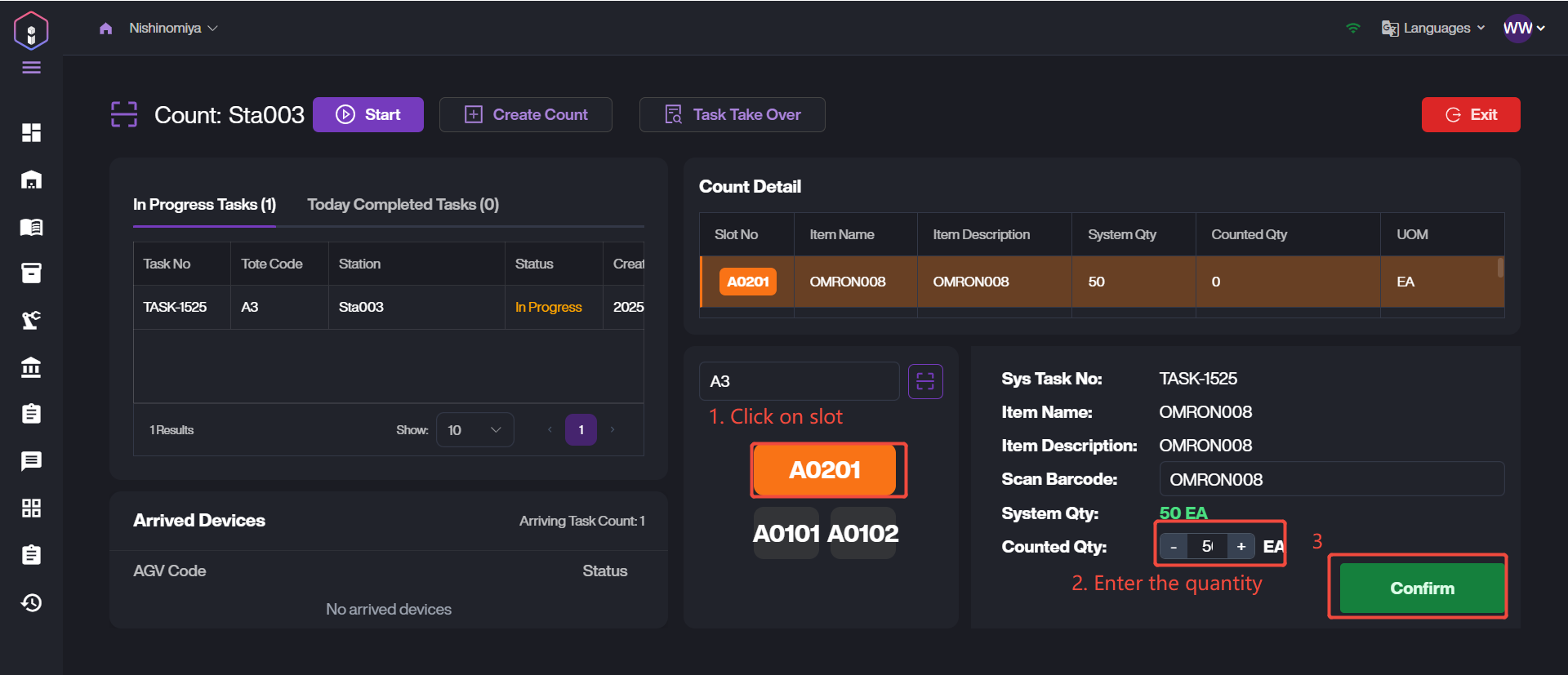

Scan or input the tote code to continue.

-

The count details, item information and tote type will be shown on the right panel.

-

Confirm the inventory of each slot. Directly click on each Slot, then modify and enter the Counted Qty in the bottom right corner.

-

Confirm the quantity.

- If this tote code has multiple slots, please repeat Step 4 and Step 5 to count all items.