Return As a Used Item

In RMS, you can handle and dispose returned goods from customers. Upon receival of the returned packages, the status of the packages and goods should be logged, and based on whether the goods are in a condition suitable for resales, they might be put back on shelves for other orders, or be disposed of and scrapped. If your customer supports restocking returned items as used ones, certain setup should be configured beforehand.

Organization Setup

-

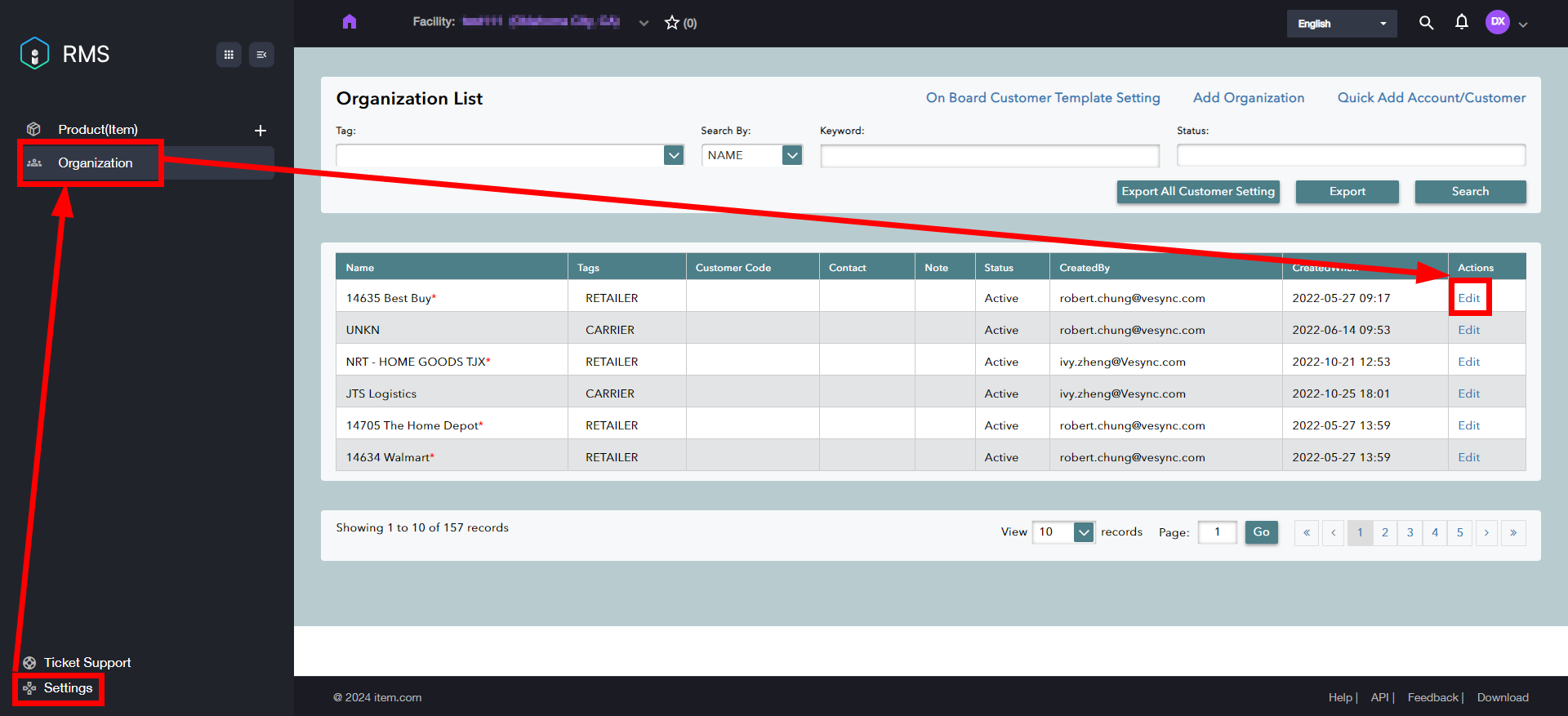

Log into RMS and navigate to Settings > Organization. Find the desired organization and click Edit in the Actions column. Or, you can also access the page in WMS > Settings > Organization.

-

Click Advanced Mode in the upper right corner, and then go to the Customer tab. Scroll down the page and expand the RMS menu.

-

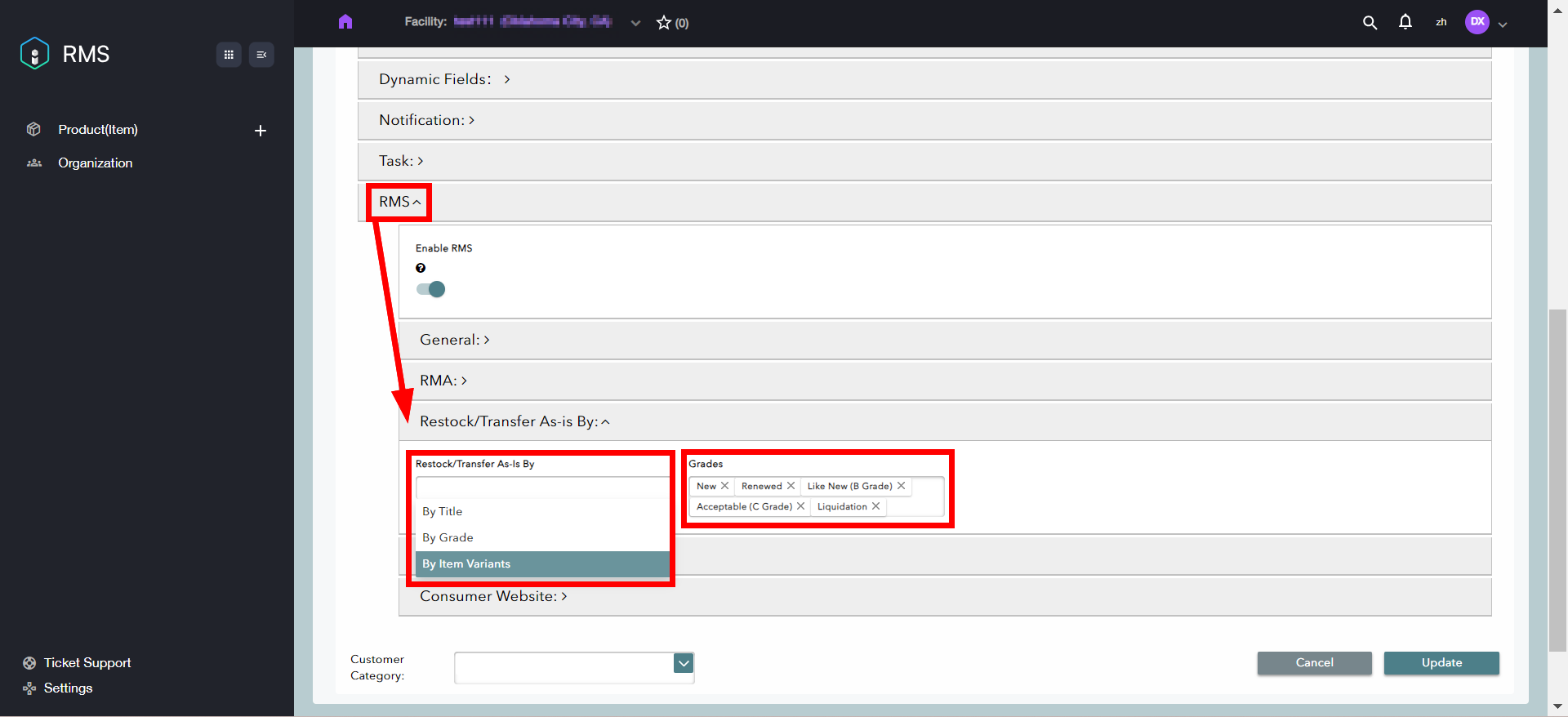

Expand the Restock/Transfer As-is By sub-menu. First select an option and if the option is By Grade or By Item Variants, it is also necessary to set the specific grades. The three options are explained in the following list.

| Restock/Transfer As-Is By | Description |

|---|---|

| By Title | This option means this organization accepts returns but will not restock the returns as used items. |

| By Grade | Used items are supported by this option. When it is selected and configured, during visual screening of the returned items, a new property named Grade for these items needs to be set, which will be synced to WMS for the corresponding items as well. |

| By Item Variants | This option works similarly to By Grade; only after the Grade is set during visual screening, except when the Grade is set as New in which case this item will still be considered as the same with the original, the system will search for items named with this product’s name + the set grade, such as tv_renewed; if no such item is found, then it will be generated both in RMS and WMS, and this new item will be used in later workflows. |

Be noted that if this setting is not configured and left blank, then by default this customer does not support Return as a Used Item.

- Click Update in the lower right corner to save the modification.

This topic aims to instruct the procedure for returning and restocking as a used item, therefore, either By Grade or By Item Variants can be selected.

Receive Returned Packages

-

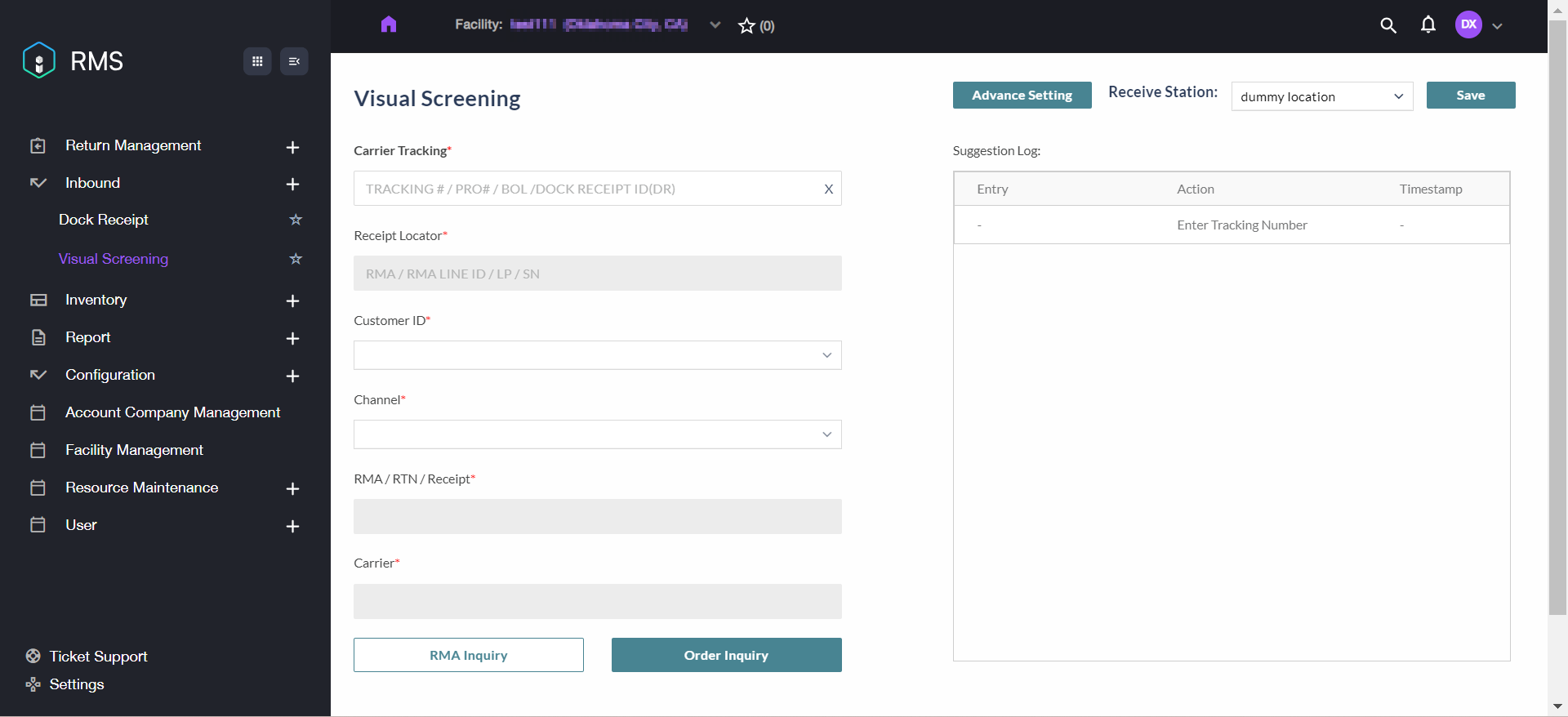

Log into RMS and navigate to Inbound > Visual Screening. The Suggestion Log to the right side automatically lists suggested follow-up steps.

-

(Optional) The Receive Station in the top right corner provides a dropdown menu and is usually set to the current location and saved without constant changing. You can change it to a desired one if needed.

-

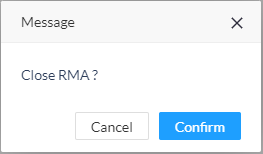

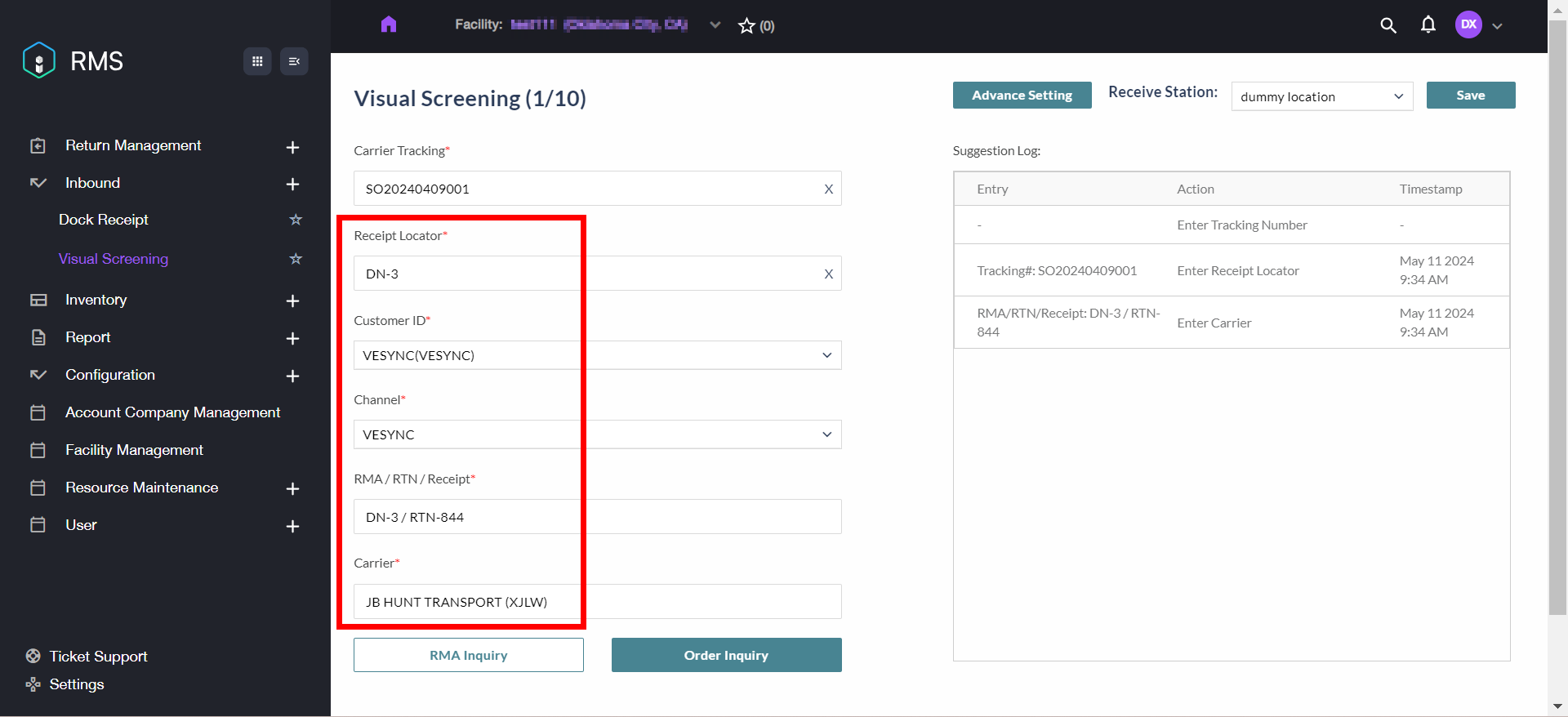

Enter the Tracking No., Pro No., BOL, or Dock Receipt (DR) for the returned goods, by manual input or scanning, into the Carrier Tracking text box. Then press Enter in the keyboard. Usually, the following fields are auto-populated.

Note

- If some fields are not auto-populated, enter the required fields manually into the text boxes or into popup dialog boxes.

- If you are not sure about the exact information for certain fields, you can click RMA Inquiry or Order Inquiry and search for needed RMA or order information. If a Create Pre-Authorized Receipt dialog box keeps popping up, possible reasons might be the order or the RMA for this order lacks certain crucial information; in this case, you may turn to our technical support team for help.

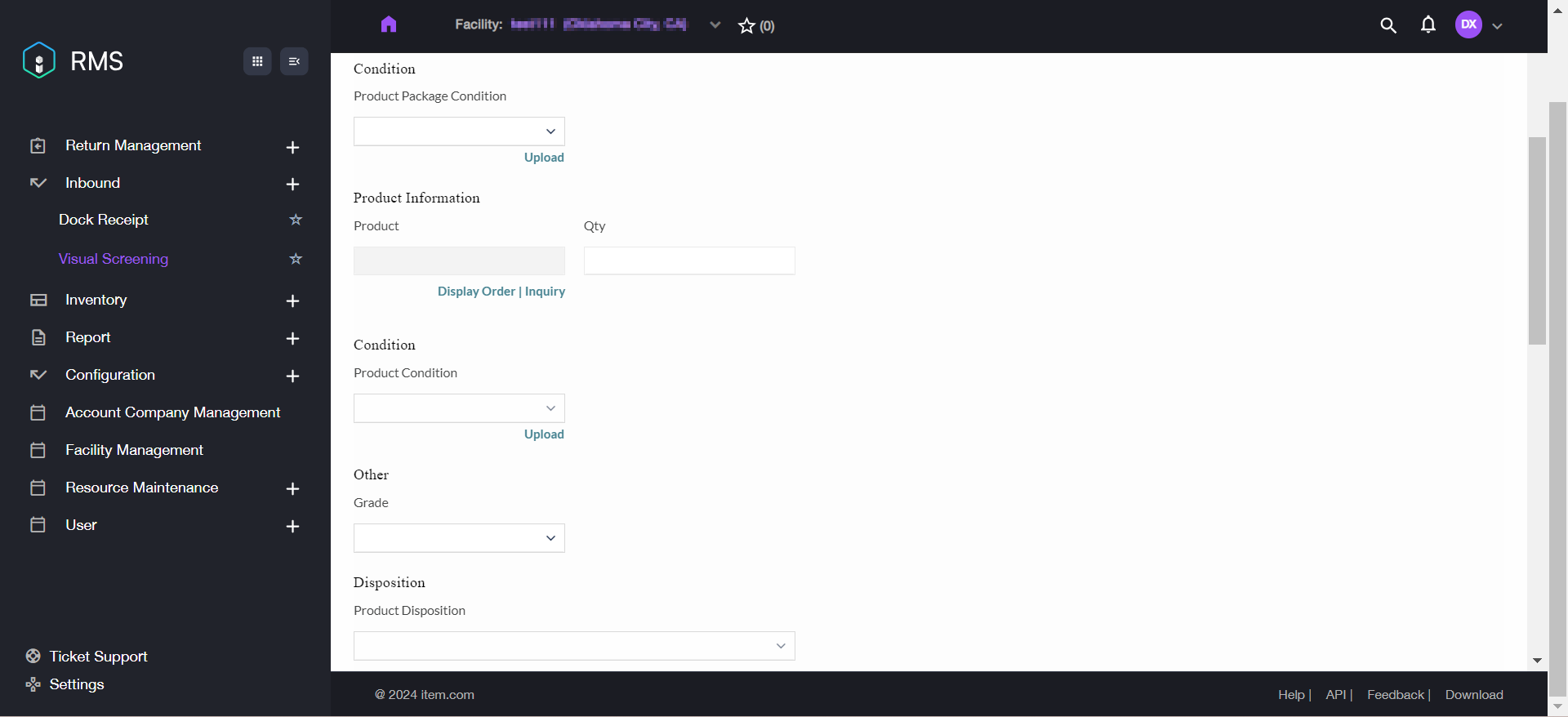

- Scroll down the webpage, so the visual screening results section is shown and to be filled. Enter each field after careful screening the returned packages and goods.

| Field | Description |

|---|---|

| Condition (Product Package Condition) | Select the condition of the item packages. If desired, click Upload to upload photos of the packages. Press Enter to continue. |

| Product Information | First fill in the item name, press Enter and then fill in the received quantity and also press Enter to continue. If not sure about the items, you can click Display Order to view the items within the order or Inquiry to search. Be noted that only one item line can be operated here at one time. |

| Condition (Product condition) | Select the condition of the items. If desired, click Upload to upload photos. Press Enter to continue. |

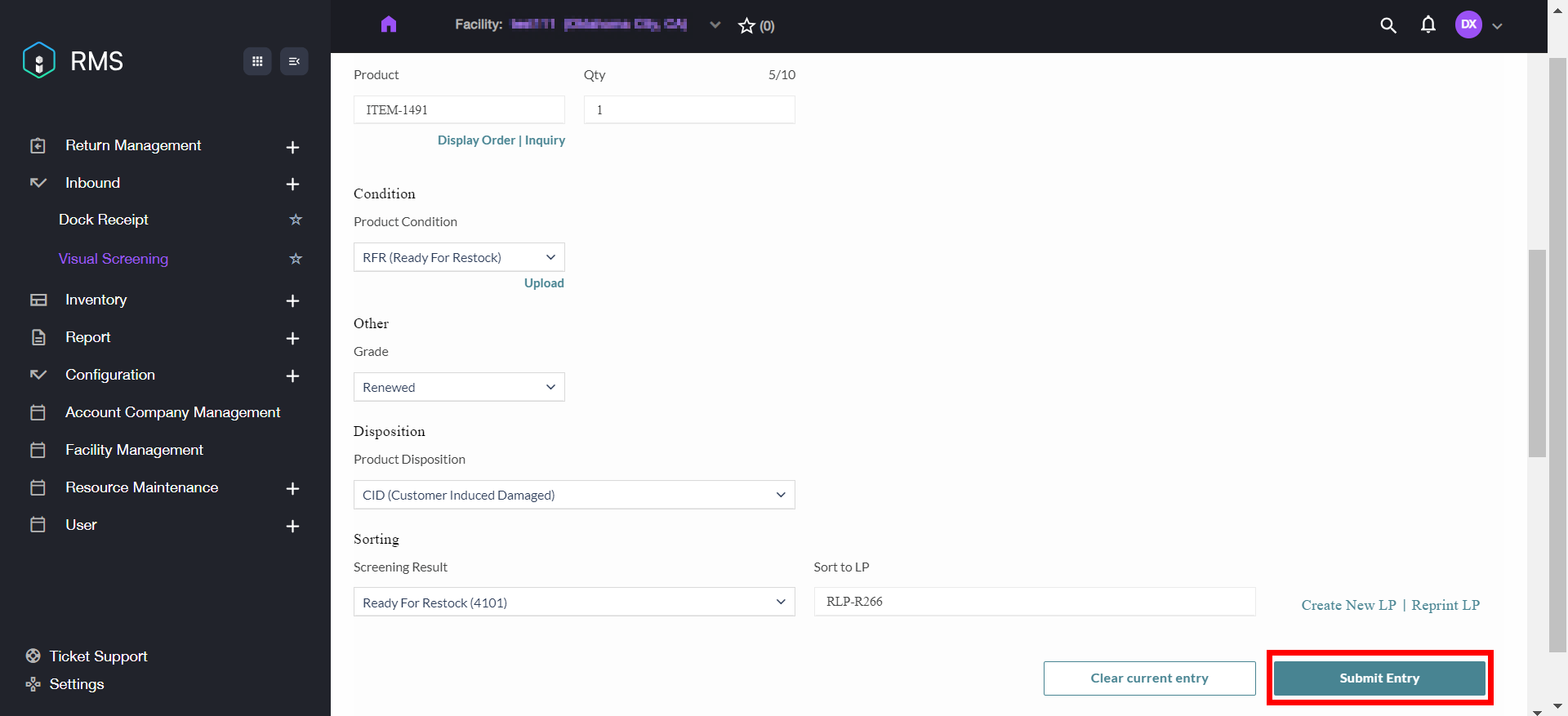

| Other (Grade) | (Optional, available only if this organization is configured as By Grade or By Item Variants in the Restock/Transfer As-is By menu of its properties; refer to the previous section on Organization Setup) Select the grade of the products. If the returned item is considered New, then it can be restocked back to the inventory of the original item; for other grades, the item will be considered as Used. |

| Disposition | Select the way of disposition for the items. Press Enter to continue. |

| Sorting | First select the screening result, namely further process to handle the items. Then fill in the LP for sorting the items. Or you can click Create New LP to generate a new LP. Be noted that the result selected here will affect options for later actions. |

Note: The following lists suggestions for some common scenarios:

- Ready For Restock: Select this one if the item is to be restocked to inventory and used for other orders.

- Pending Scrap: Select this one if the item is to be scrapped.

- Pending Repair: Select this one if the item is to be repaired and later process will be up to repair results.

- Click Submit Entry.

Note:

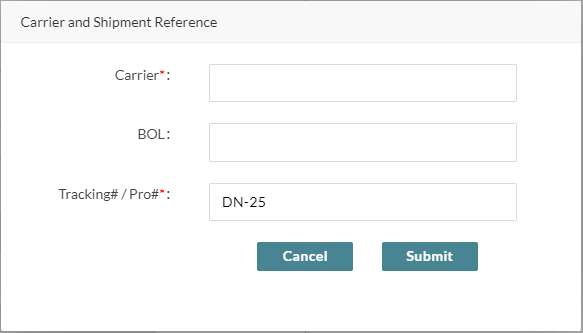

If all the quantities of all items have been handled in the visual screening here, when submitting the entry, a confirmation dialog box pops up, asking whether to close the RMA or not. The common practice, as well as the suggestion here, is that, if there is more than one item line in this returned package, select Cancel, in case of needs to return other item lines; if not, select Confirm. The reason is that only when an RMA is not closed can another return handling process be created in RMS later for other items in this order.

-

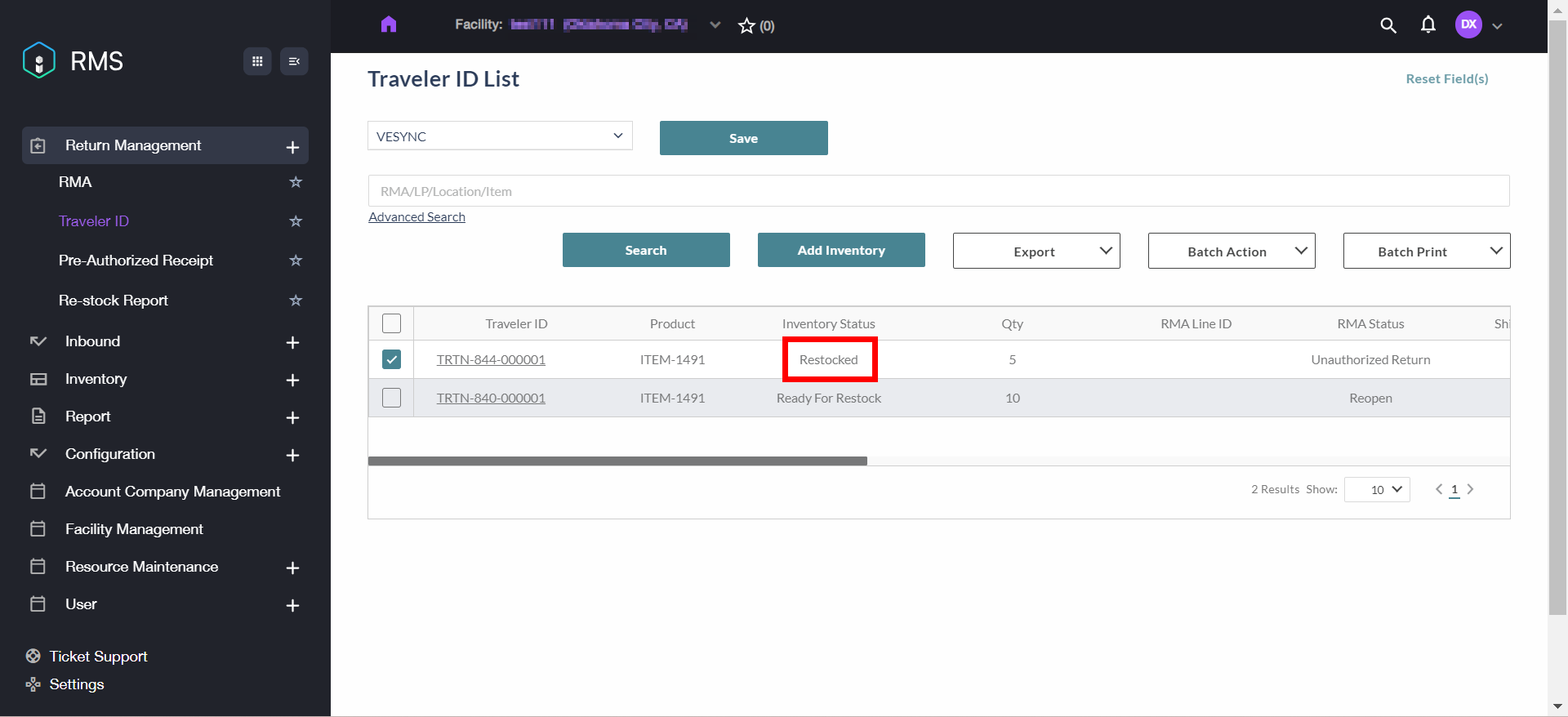

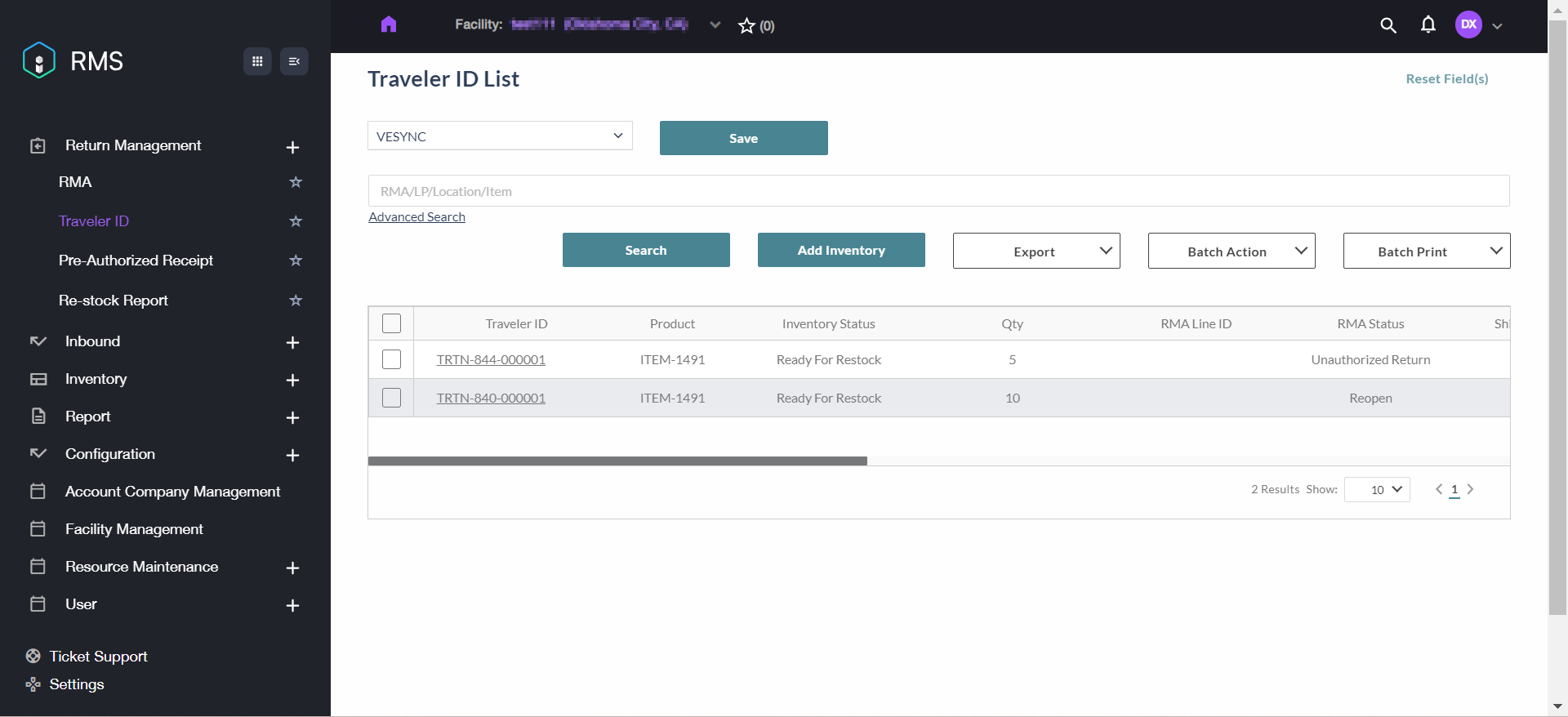

A Traveler ID, which is an ID for each return handling process, is generated for the current process. Navigate to Return Management > Traveler ID. All the Traveler IDs are shown here, with different status.

-

If the shown customer ID is not the desired one, enter it and click Save. Enter other keywords if needed. Then click Search.

-

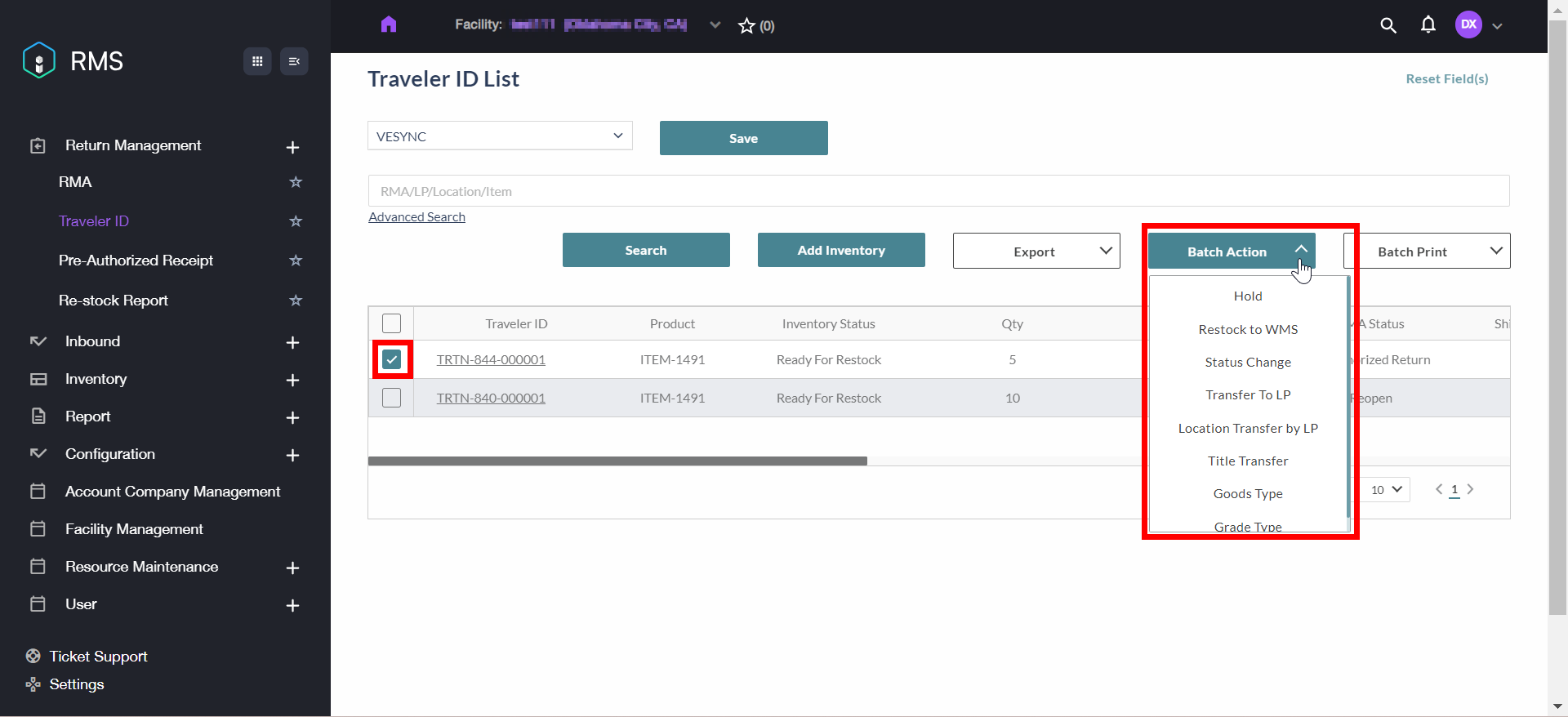

Select the desired Traveler ID (by checking the checkbox at the beginning of the row), and click Batch Action. The dropdown menu is displayed.

Be noted that the options in the menu vary or might be empty with the Traveler IDs’ status.

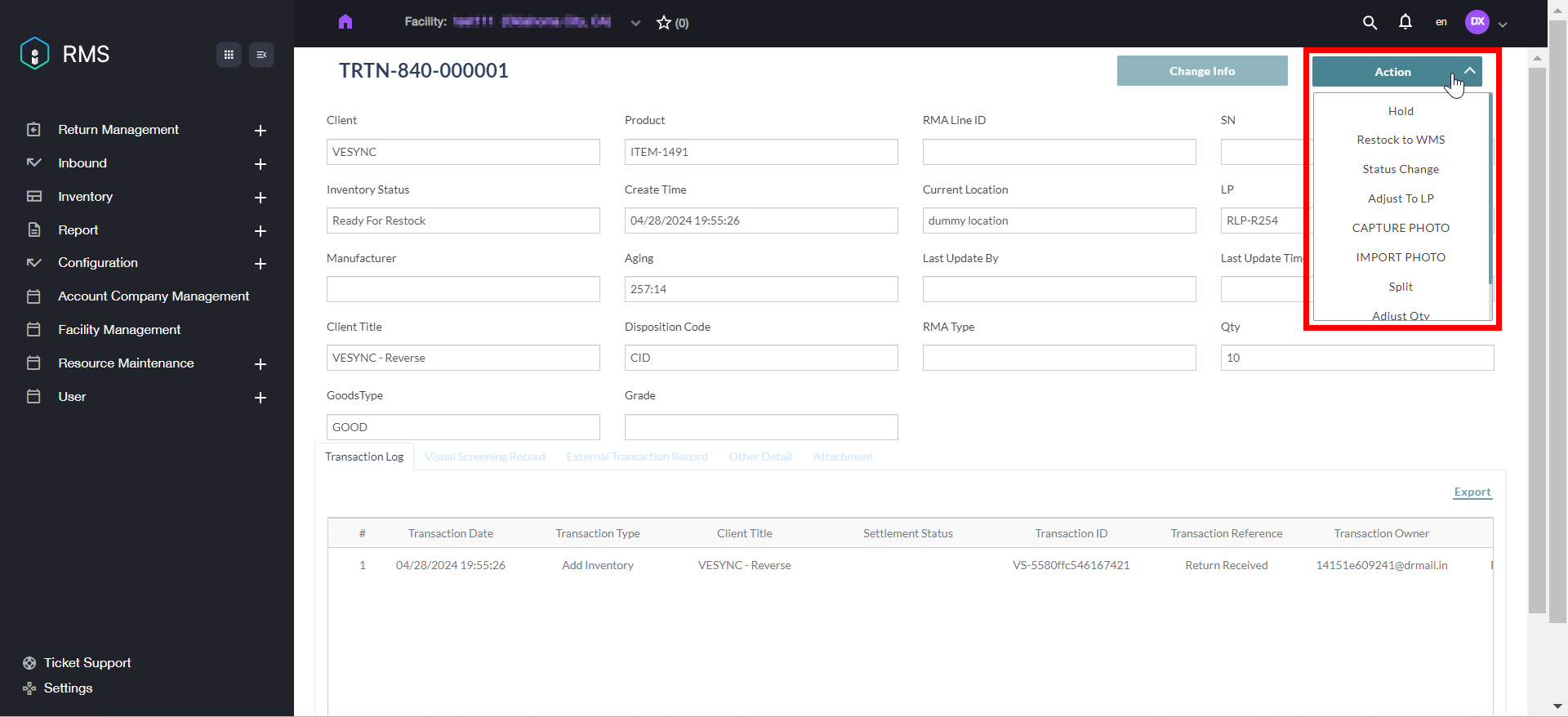

Besides Batch Action which is a batch action for multiple Traveler IDs, you can also click a specific Traveler ID and go to Action in the upper right corner of the details page.

Return as a Used Item

This option means the goods are considered as used but in a condition that can be put back to inventory of either the original items or an auto-created new one, and be used for other orders. Normally the screening result is Ready For Restock.

-

In the Batch Action dropdown menu, select Restock to WMS.

-

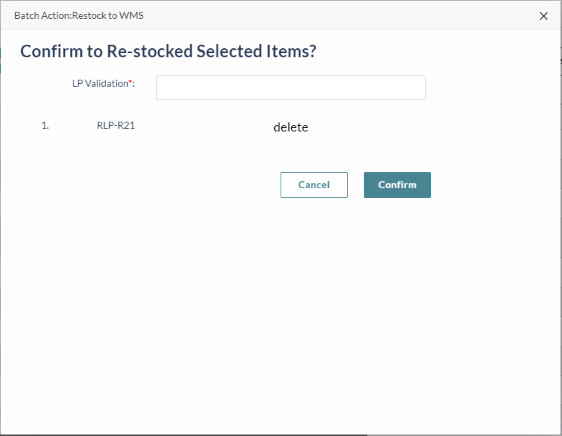

In the popup dialog box, copy the displayed RLP number and paste it back into the text box, or enter the right one directly.

-

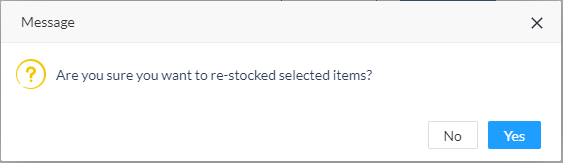

Click Confirm, and in the confirmation dialog box, click Yes.

-

The status of this Traveler ID is updated from Ready For Restock to Restocked. So far, the operation in RMS has been completed. Next, you (or other personnel in charge) need to sign in the WMS app and create a putaway task to restock the mentioned returned items to inventory, so that they are available for other orders. These items are listed (added either directly back to the identical items if any, for those organizations with the customer setting for RMS as By Grade, or to a newly auto-created item specifically named, for those organizations set as By Item Variants) in RMS > Inventory > Inventory List, or in WMS > Inventory > Inventory > Inventory List.