Empty Tote Inbound

The Empty Tote Inbound function is designed to manage the entry of empty totes into the warehouse through automated coordination between WCS, RCS, and WES systems. This process ensures that totes are registered, routed, and stored efficiently with minimal manual intervention.

Workflow View

When an operator clicks Start button at the Empty Tote Inbound workstation, the following process is triggered:

1. Tote Request Generation

-

WCS calculates the number of empty tote requests based on the number of queue slots (buffer positions) configured at the station.

-

For example, if a station supports 4 buffer positions, WCS will create 4 tote request tasks.

-

Tasks are dispatched to RCS, which handles the empty vehicle routing.

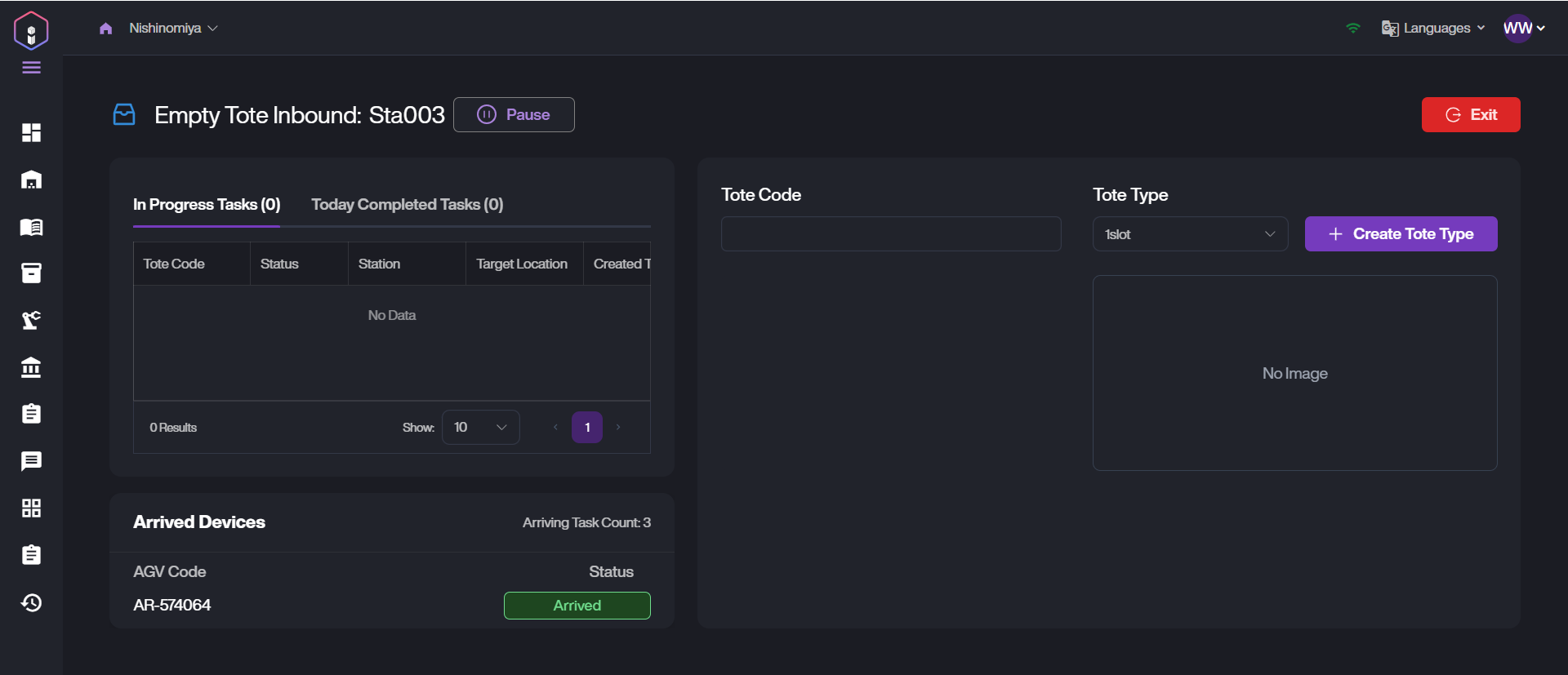

2. Vehicle Arrival and Tote Scanning

-

As each vehicle (e.g., robot or shuttle) arrives at the station, WCS updates the UI to show vehicle information.

-

The system enables box scanning mode, allowing the operator to place a tote on the vehicle and scan the tote barcode using either a handheld scanner or a fixed BCR scanner.

3. Tote Registration and Inbound Request

-

After scanning, WCS registers the tote and sends an Empty Tote Inbound Request to WES.

-

WES checks for available locations in the warehouse.

-

If no locations are available, WCS displays the message:

No available location.on workstation. -

If a location is available, WES generates a PutAway action.

4. Inbound Job Execution

-

WCS creates a job and initiates execution.

-

RCS takes over the job, transports the tote to the designated location, and completes the task upon arrival.

-

The empty tote inbound task is now fully complete.

Additional Logic & Explanations

1. Empty Tote Request Count Logic

-

The number of ongoing tote requests must always match the configured queue size at the station.

-

As one vehicle arrives and completes a task, WCS will immediately generate a new tote request to maintain the buffer count.

2. Manufacturer-Based Dispatch Mode

- If the map configuration is set to manufacturer dispatch mode, commands are delivered via a protocol template to the equipment.

3. BCR Scanning Behavior

-

The system supports both manual and automatic scanning.

-

When using a fixed BCR scanner, the scanned barcode is:

-

Report the scanned tote number to the system.

-

Auto-filled into the input field upon the system receives the information.

-

Auto-submitted with automatic "Enter" action to trigger tote registration.

-

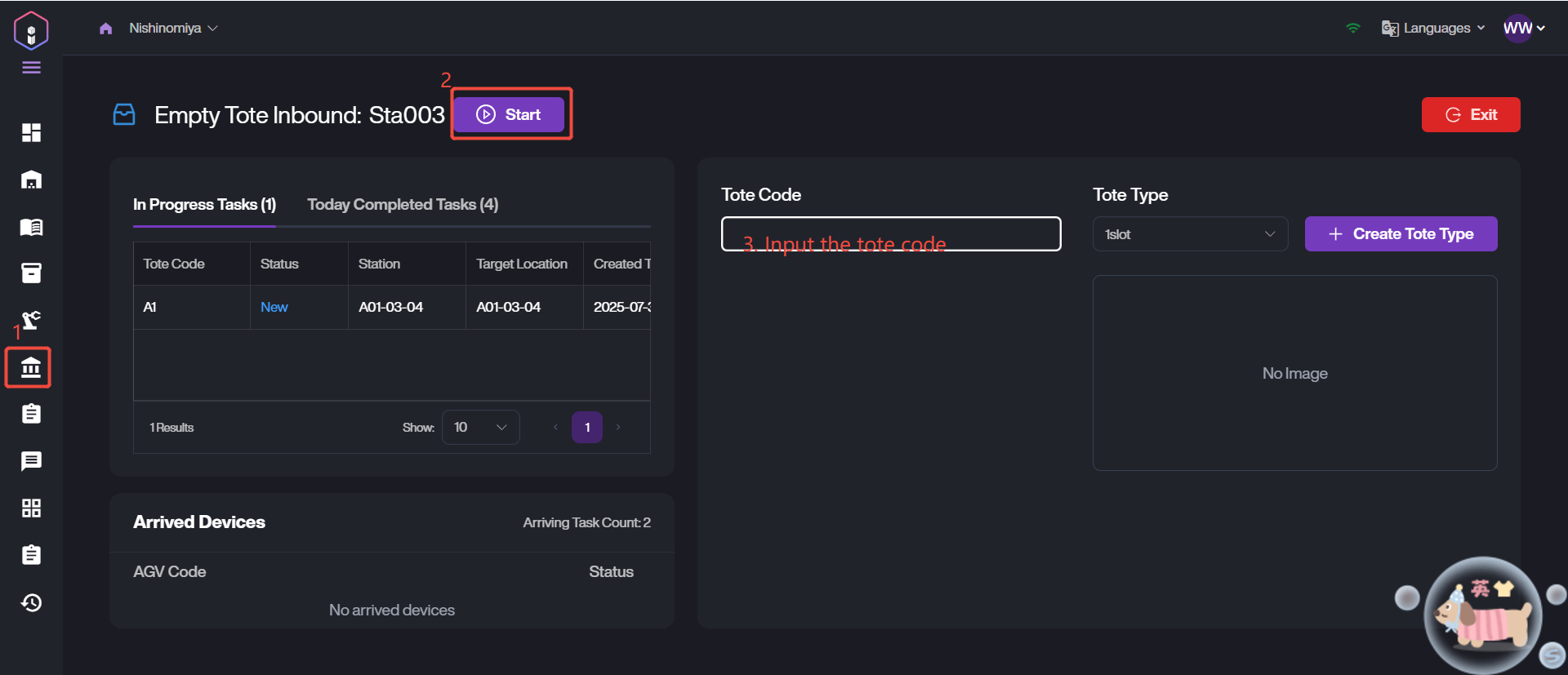

Workstation Page Features

The Empty Tote Inbound workstation page is divided into two sections for efficient operational visibility:

Left Panel

Start: Triggers the creation of empty tote requests.

Arrived Device List: Displays the status and ID of robots or shuttles en route to the station for tote pickup.

Put Away Job List: Shows the list of put away jobs already created and pending execution.

Right Panel

Tote Details: Display the tote ID and tote type. If a matching tote type exists in the Container Management module and has a photo uploaded, the image will be displayed here.

Create New Tote: If no matching tote type is available, operators can manually create a new tote type.

Status Messages: Real-time feedback such as “No available storage location” or “Start inbound!”.

Exit: Triggers the cancellation of empty tote inbound process. The following actions will be executed once the Exit button is clicked:

-

Stop dispatching empty totes and generating new empty tote requests.

-

Cancel unfinished empty tote requests.

-

Release vehicles that have already arrived at the station.

-

Finalize cancellation.

Web Operation

-

Go to Manual Station > Empty Tote Inbound.

-

Click Start to begin the process.

-

Enter the tote code. Then the tote will be carried to this station for inbound.